Transformer connections are exposed to environmental influences including mechanical impacts, water, oil, direct sunlight and ozone, all of which can negatively influence the lifetime of the connections. The new Han® HPR HPTC series was specially developed for railway transformer applications. The Han® HPR standard enables use in harsh environments. Shielding can be reached without shrinking and taping.

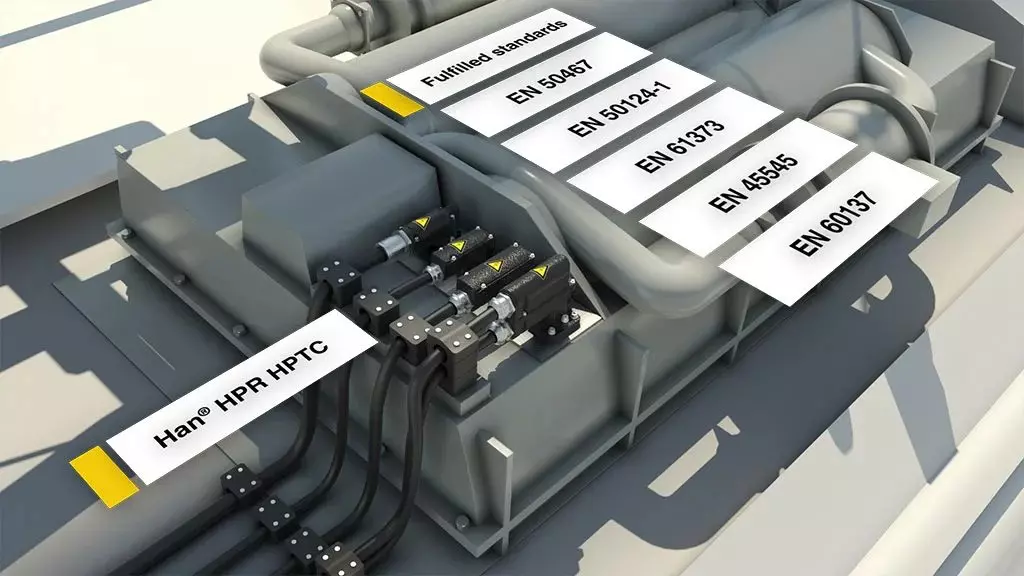

HARTING Han® HPR HPTC - High Performance Transformer Connectors

The new system meets the requirements of easy handling, a low number of components used and maximum security. On the cable side, a crimped contact is inserted into a three-part, touch-proof insulating body. In addition, there is a cable gland that protects against dust and humidity and is also part of the shielding, absorbing differential currents and transmitting them to the housing.

The housing is metallically contacting on all sides, i.e. the cover and underside are connected over the entire contact surface. This feature is unique, as there is no other transformer connector that has been specially designed for shielded connections.

The aim of collecting residual currents and discharging them via the housing can be achieved with the Han® HPR HPTC 800 because it has two separate contact areas.

It is directly connected to the flanged housing via a surface on the underside. On the upper side there is a thread for a potential tag which discharges the remaining differential currents.

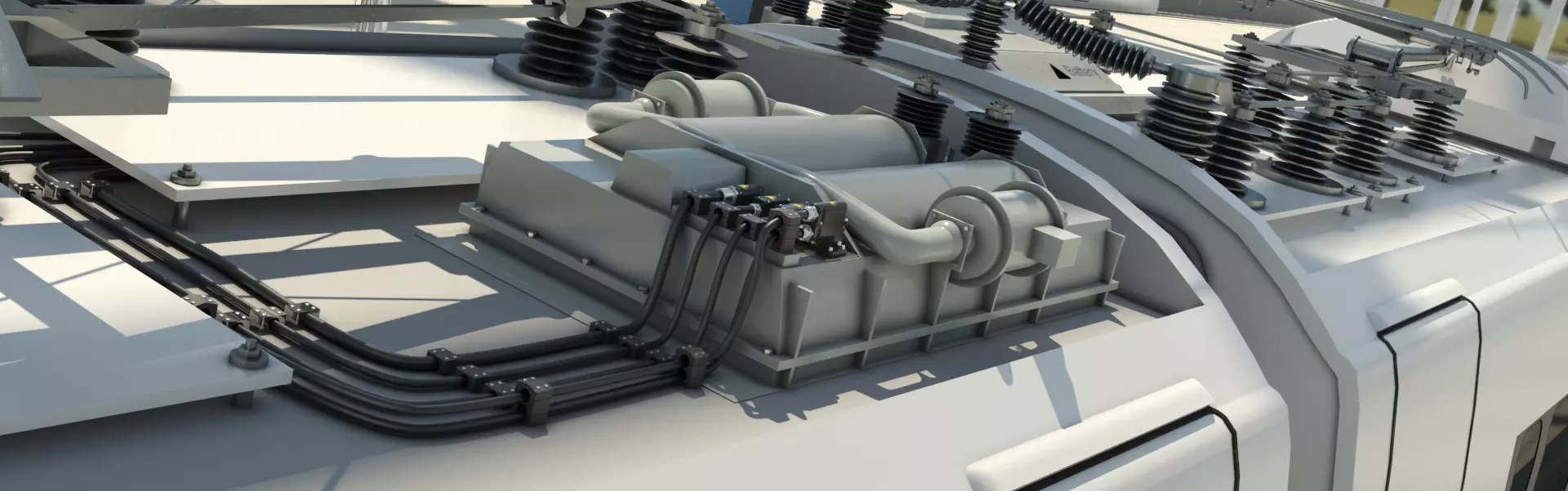

Typical installation environment for the Han® HPR HPTC

HARTING Han® HPR HPTC - High Performance Transformer Connectors

No shrinking or taping necessary

The Han® HPR HPTC also simplifies installation. No shrinking or taping is required to set up transformer connections and the interfaces are quick to prepare: Crimp the contacts, insert the insulating body with shielding into the housing, close the cover - and the cable side is ready.

Find out more about this solution

The modular system offers a flexible expandability

Minimum inventory needed due to coding system

Numerous encoding options are available. Two coding elements in the mounted housing open up 16 different combination possibilities.

One connector type is therefore sufficient for the transformer connection, everything else can be controlled via coding. This significantly reduces the inventory needed and helps to reduce costs.

One for all: Han® HPR HPTC coding system

Retrofit

The Han® HPR HPTC series is retrofit. The transformer side has the same dimensions as existing solutions in the market. Existing contours on the transformer can be reused, meaning design changes are not necessary. Customers can use the HARTING housing system to replace former solutions.

Your benefits at a glance:

Longer lifetime due to Han® HPR standard metal hoods and housings for harsh environments

Time savings due to easy installation and shielding without shrinking or taping

Cost savings due to minimum inventory needed based on efficient coding system

Secure solution according to relevant railway standards (EN 50467, EN 50124-1, EN 61373, EN 45545, EN 60137)

Shock- and vibration proofed system