Strong signal transmission requires less space

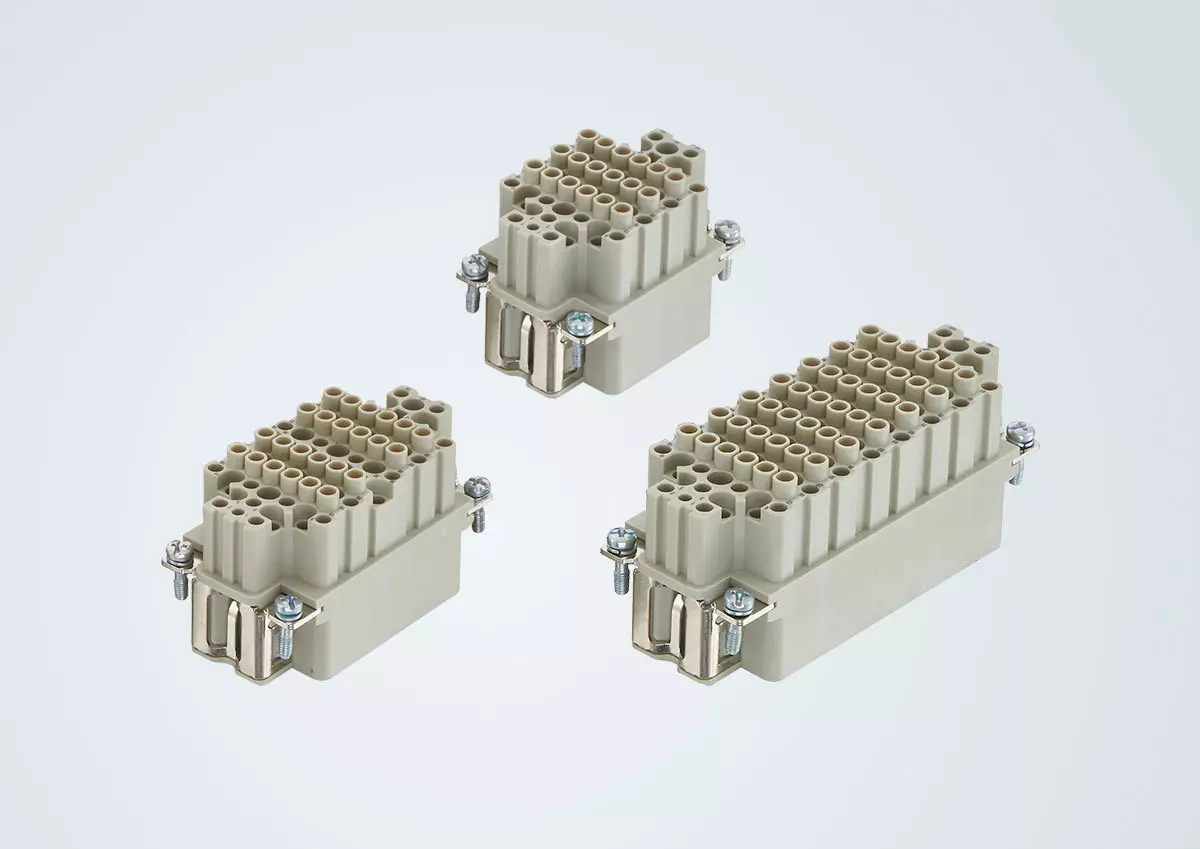

The new triple “D” inserts are standing for maximum contact density – up to 130% plus, compared to previous standards – without reducing the rated voltage.

The need for space-saving solutions is a fundamental theme in machinery, robotics and automation. It is what prompted HARTING’s development of the Han D® Series, which stands for high contact density and small dimensions. The Han® DDD has twice the number of contacts than the previous standard Han® DD – yet retains the same dimensions and electrical characteristics.

No reduction in rated voltage

The “Triple D” can transmit signals or power with max. 107 contacts. The electrical power is equivalent to that of its sister product, the Han DD® (max. 250 V / 10 A).

To simplify handling in automation or robotics, HARTING also offers accessories such as grip panels and guiding pins/bushes.

Up to 107 contacts without reducing the nominal voltage: Han® DDD inserts

No additional tools for PE-connection necessary

As well as space saving benefits, the Han® DDD inserts can also help optimise wiring processes. The installer just needs to deal with one termination technology for electrical and PE contacts. Additional accessories and tools are not necessary.

The Han® DDD can thus optimise the use of interfaces in conventional control cabinets.

Existing contact surfaces for interfaces in robotics, for example, are thereby utilised more efficiently. Space-saving applications are possible in all industrial sectors where electrical connections play a role.

Your benefits at a glance:

Up to 130% higher contact density without reduction in rated voltage (compared to well known Han® DD inserts)

Cost reduction: Increased number of contacts per interface

Process optimisation: One termination technology for electrical and PE contacts

Reduction of assembly times: No additional accessories and tools for PE-connection necessary

Additional space savings: Connector size can be reduced