Get detailed information about cutting / stripping, crimping

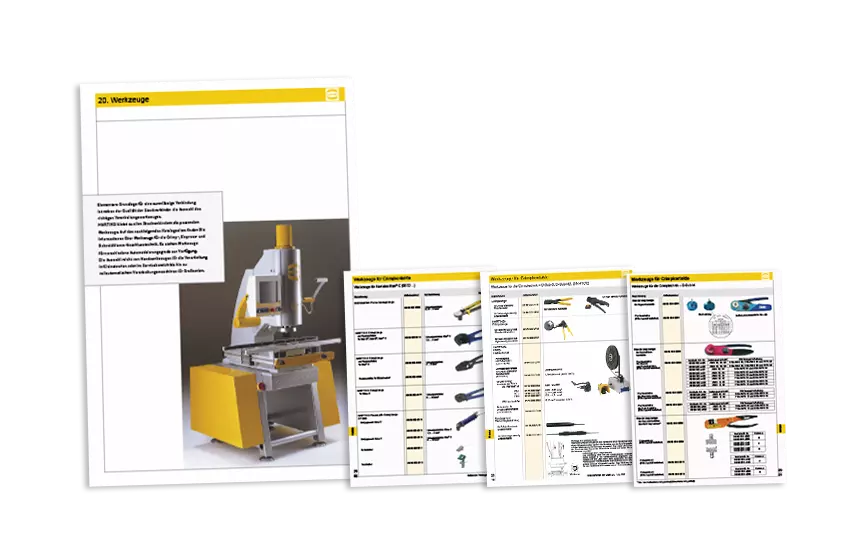

Tools

HARTING's tool portfolio ranges from simple assembly and disassembly tools, manual and semi-automatic hand tools to fully automated machines.

Our range of tools

The HARTING range of tools extends from simple assembly and disassembly tools to crimping tools and hand tools through to fully automated machines for the efficient processing of contacts and connectors. Please have a look around to see which tools you need.

Feel free to contact us - we're happy to advise you!

This makes us strong

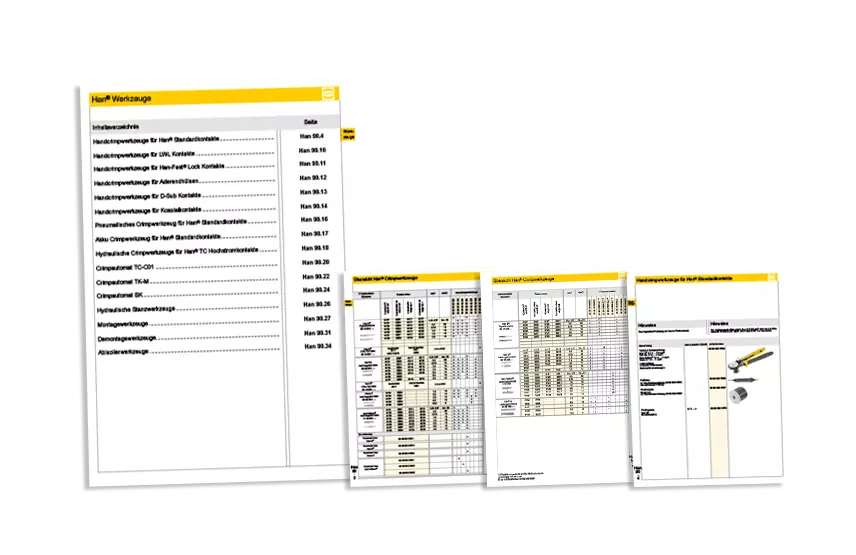

Han® Industrial Connectors - Tools

This clear selection guide in PDF format gives you a complete overview of the comprehensive range of HARTING products on the wide-ranging Han® industrial connector market.

HARTING crimping tools

This clear selection guide in PDF format gives you a complete overview of the comprehensive range of HARTING products on the wide-ranging crimping tool market.

HARTING Device Connectivity - Tools

This clear selection guide in PDF format gives you a complete overview of the comprehensive HARTING product range for PCB connection technology.