The value of a wind turbine (WT) is not only measured by the investments into machines and site development, but also in the way it is used over the whole lifetime. In the long run, components which simplify installation and maintenance can improve the value of the plant enormously. If a wind turbine manufacturer uses pluggable connectors for the electrical connections between WT modules, this can lower both the investment costs (CAPEX) and the operational costs (OPEX).

Easy installation and maintenance of wind turbines

A good example of a regularly replaced component on a wind turbine is the slip ring – the interface between the stationary nacelle and rotating hub. The slip ring is used to transmit the signals for the pitch systems that determine the angle of incidence of the rotor blades.

This interface can have a pluggable design: HARTING’s solution uses Han-Modular® inserts and the Han-Modular® hinged frame.

The plug solution offers many advantages over permanently attached wiring. The slip ring can be replaced more quickly, thereby reducing downtimes. During maintenance in the service workshop, the slip ring can be replaced without intervention in the pitch system and without dismantling the connecting cables. The service fitters in the nacelle do not require special tools. This reduces costs for maintenance and repair.

Slip-ring connection at a wind turbine

Investment costs under control

There are good cost-saving opportunities associated with using plug connectors for the initial investments as well as the installation costs. Power cabinets in the wind turbine are still mostly hardwired.

They are hardwired and tested during assembly in the factory, then the connections are disconnected and restored at the system level in order to repeat the process after a further disconnection in the field.

The use of pluggable connectors speeds up the installation process and increases the modularity of the WT. The pluggable connectors also open up options for the modularisation of the power cabinets.

Connectivity in Wind Turbines

This PDF White paper will show you how connectors could increase the efficiency of wind turbines and reduce the CAPEX and OPEX (PDF | 5 MB | 22 pages)

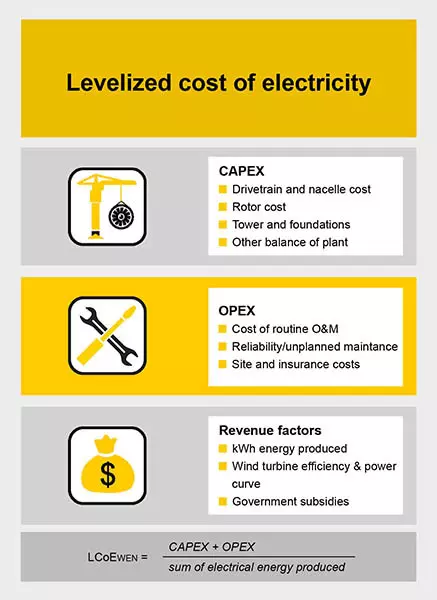

Levelized cost of electricity

The value of pluggable connections for installing and operating a wind turbine can be illustrated with numerous other application examples.

The adjacent diagram shows the areas in which plug connectors simplify and thereby enable savings in installation/investment (CAPEX) and operations (OPEX). It is worth highlighting that significant savings can be made using plug connectors even in the investment phase, with assembly and installation in the field.

This reduces the costs for installation of wind parks by shortening assembly processes. Plug connectors help any installation fitter who must attach components at inaccessible angles in the nacelle and tower.

In the long run, an evaluation of costs incurred for capital goods in a WT cannot avoid the use of pluggable connectors. The initial costs for these connectors, which incur less than 0.5% of the total investment, will already be amortised after just a few maintenance processes.

Apart from this, the installation logistics would quickly reach their limits at current conventional plant sizes (onshore average: 3.3 MW) without a modular design that uses plug connectors.

Levelised costs of electricity

Your benefits at a glance:

Savings of time and cost due to rear mounting options

Separate pre-assembly of entire cable harnesses possible

Reduction of manufacturing cost by better division of labour

Additional time savings by using Han® ES Press rapid termination

White Paper Download

Learn how connectors can increase the efficiency of a wind turbine and reduce the CAPEX and OPEX costs.