Food and beverage connectors

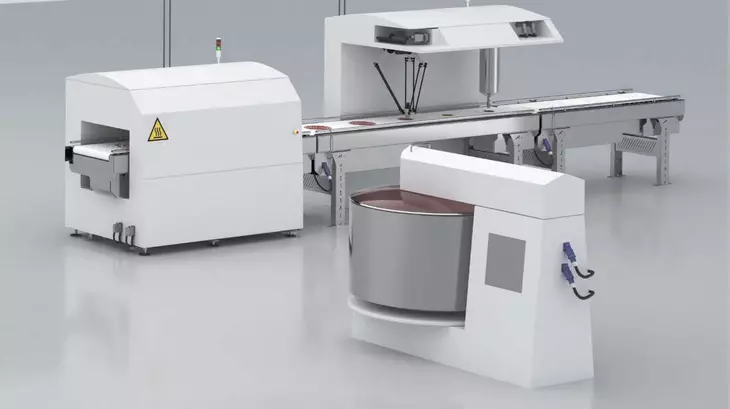

Connectors and cable assemblies especially developed for the food and beverage industry are the perfect fit for environments with strict hygienic requirements and where quick cleaning cycles and fast facility installations are needed.

The requirements for production plants in the food and beverage industry are high. It is crucial to avoid contaminations caused by residues of foodstuff on components, such as motors and connectors. This is achieved by regular high-pressure cleaning cycles and caustic cleaning chemicals. In order to make a plant resistant against these kind of cleanings, its components have to meet certain conditions.

On the other hand side food and beverage production lines need to be flexible. Tools needs to be changed frequently to set up the line from one product to the next. In the case of a downtime defective components needs to be replaced quickly.

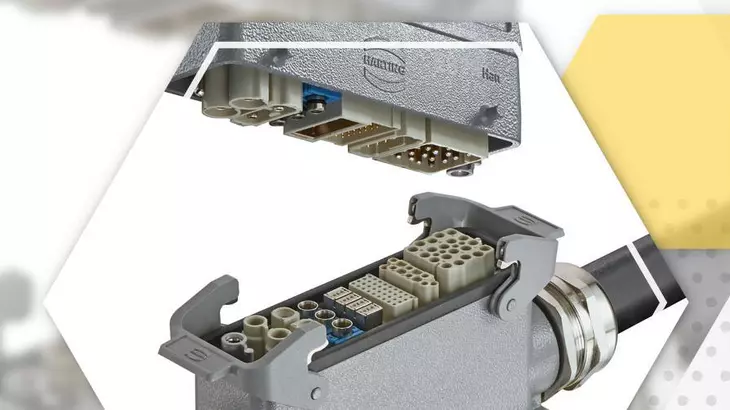

HARTING is offering food and beverage connectors which are reliable against water jets and aggressive cleaning agents. Customers can choose between connectors and cable assemblies based on:

High-performance plastic connectors, such as Han® F+B connector series

Connectors made from stainless steel, such as the Han® INOX connector series

Related shortcuts

The perfect fit for an environment with high standards

The pre-assembled Han® F+B system cabling, which arrives at the customer as an already fully tested assembly, can be connected simply as a plug & play solution. This simplifies, saves time and prevents errors during installation. This reduces costs and minimises downtimes.

F+B hybrid system cabling routes all three industrial lifelines (data, signal and power) in one cable and therefore ensures as a single-cable system that interfaces are reduced to a minimum. The control range enables up to 10 A and 250 V. In the high-power range, a current carrying capacity of up to 20 A and a voltage of up to 400 V is possible. In addition, the fieldbus integration (CAT5e) enables transfer rates of up to 100 Mbit/s. This cabling solution achieves protection class IP69 when plugged in.

In addition to the Han® F+B hybrid version for data, signals and power, HARTING also offers this cabling solution with 17D contact carriers for power and signal transmission. This variant is combines the Han® F+B enclosure with the well-known Han® D contacts, which allow a current carrying capacity of up to 10 A at 400 V.

Another feature of the Han® F+B cable is its Ecolab® approval, which testifies to its resistance against highly aggressive cleaning agents. Han® F+B system cabling ensures outstanding safety – all assemblies are 100% checked in order to guarantee high quality standards.

Industries & Solutions

Best Practices

Web-Seminars

News & Events

Engineering Data & Services

CAD data, product data manager, distributors availability, free samples & more.

Discover the HARTING Engineering Data & Services to support your project as best as possible. For each product in our digital catalogue you will find further engineering data and services:

CAD data, data sheets and type sheets

Product selectors with multiple attributes

Individually data packages

Configuration and customization

Individual notes and deratings

Free sample service