Simplified installation of control cabinets

Machine manufacturers can save a lot of time and effort during installation if the systems are no longer delivered with open cable ends in the traditional way. A globally active special purpose machine manufacturer for pharmaceutical products is therefore equipping its machines with pre-assembled cable harnesses that are directly connected to the control cabinet using connectors. This prevents wiring faults and reduces the installation time by more than 30 percent.

"Over 80 percent of the special purpose machines are exported. However, very often there is a lack of qualified personnel during the installation and commissioning on site. This can be very expensive if someone has to travel extra to eliminate wiring faults," says René Heiden, Operations Manager at SUATEC GmbH, describing a typical installation challenge on international construction sites.

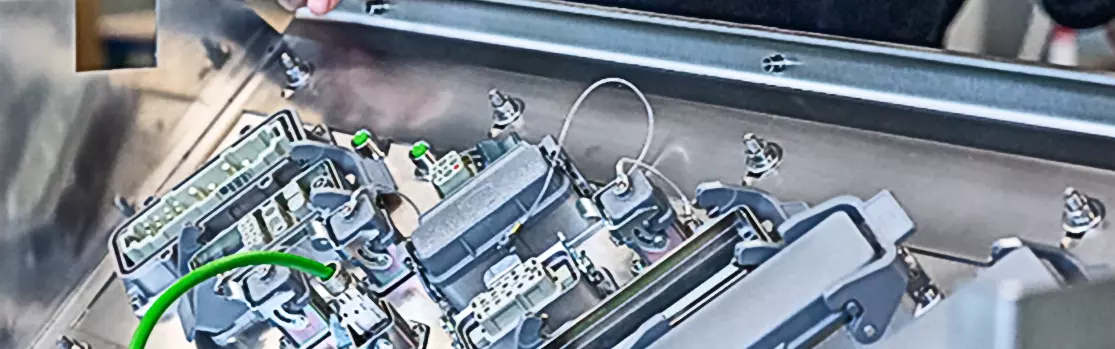

SUATEC GmbH with over 50 employees creates automation and engineering solutions for process and plant technology. This also includes control cabinet construction for the special purpose machine manufacturer. "The machine is connected to a cable harness comprising 50 individual cables. Each cable has another 4 to 25 individual strands that must then be stripped, fitted with contacts and wired on site. This is where mistakes occur. The machine manufacturer wanted to prevent this by simplifying the cabling by pre-assembling them with connectors", the SUATEC works manager explains.

Plugging pre-assembled cable harnesses directly into the control cabinet

Guido Steenbock (HARTING left), and Rene Heiden (SUATEC GmbH, right) on the joint project. The special purpose machine manufacturer wanted to simplify the cabling and deliver its systems pre-assembled with connectors.

The large number of connections and the resulting high number of connectors from each machine to the control cabinet was a challenge. SUATEC GmbH in cooperation with the connector specialist HARTING has developed a way of routing the cable harnesses directly inside the control cabinet. The control cabinet is equipped with a special circuit board for this. It replaces a terminal strip with 200 individual low-voltage contacts. The low voltage cables are now connected directly to the circuit board. This PCB is delivered with pre-assembled adapters that fit directly into the contacts of HARTING industrial connectors. HARTING also supplies the pre-assembled cable harnesses as well as a stainless steel plate with accompanying surface mounted housings to accommodate the connectors. The solution also dispenses with the interface on the control cabinet wall and most of the internal wiring.

"The specially developed pre-assembled cables for the control cabinet, the stainless steel plate, circuit board, connectors and appropriate cable lengths for the connections in the machine were implemented as a project at HARTING. Such customised solutions are developed by a special division, HARTING Customised Solutions (HCS). HCS has specialised in such customised solutions," explains Guido Steenbock, Sales Engineer at HARTING.

We work very closely and smoothly with HARTING to ensure that the machines are delivered on time. There has not been a single case where we have not been able to solve problems quickly and satisfactorily.

Rene Heiden

Suatec GmbH

Preliminary talks for the control cabinet project were held between the special purpose machine manufacturer SUATEC GmbH and the HARTING Sales department. The technical requirements as well as the specifications for the components were then clarified with the Project Engineering department of HCS, concepts were discussed, samples were produced and ultimately a pilot series with prototypes was tested. After its release, the final electrical and EMC tests were carried out.

Installation time reduced by more than 30 percent

For the special purpose machine manufacturer, the pre-assembled cable harnesses with the mounted connectors are an important advantage. By dispensing with a terminal strip and the direct connection to a circuit board, 200 contacts no longer have to be wired individually. The cables can be manufactured in series and already equipped with connected connectors. "Everything is thus prepared for assembly on-site. Assembly of the cables is no longer complex. This reduces the assembly time by at least 30 percent," says the works manager at SUATEC GmbH, listing the benefits. The works manager cites the consistent quality provided by the standardised and quality-assured solution as a further advantage. This prevents wiring faults, and saves time and money.

"The special purpose machine manufacturer considers it important that both cable assembly and connectors as well as components such as stainless steel plates and circuit boards come from one source. All components were matched and tested by HCS," adds Guido Steenbock from HARTING. René Heiden from SUATEC GmbH finds the close cooperation important: "We work very closely and smoothly with HARTING to ensure that the machines are delivered on time. There has not even been one case where we have not been able to solve problems quickly and satisfactorily".

"Thanks to the HARTING solution, everything is prepared for assembly on-site. Assembly of the cables is no longer complex. This reduces the assembly time by at least 30 percent," says René Heiden, Works Manager at SUATEC GmbH, listing the benefits.

SUATEC GmbH with over 50 employees creates automation and engineering solutions for process and plant technology. This includes software development, visualisation and control systems as well as control cabinet construction. The company is located in Büchen about 50 km from Hamburg. SUATEC's range of services includes control systems, automation solutions and engineering for brewery and dairy technology, energy and heat technology, food and pharmaceutical industry and other industrial automation applications.