Knowledge about high voltage connectors

What are high voltage connectors (HV connectors)?

According to IEC 60050 – (IEV) 601-01-27 – "high voltage" is defined as a voltage above the low voltage level. A "high-voltage connector" therefore transports currents above 1 kV AC / 1.5 kV DC. Of course, the limit depends on conventions. In order to differentiate between individual markets or product ranges – e.g. e-mobility – other demarcations between high and low voltage are also used. For example, connectors with a rated voltage of 400 or 800 V can also be referred to as HV.

What types of high voltage connectors are there?

Design types:

Single/multiple poles (e.g. two-pole, U-shape)

Shielded/unshielded

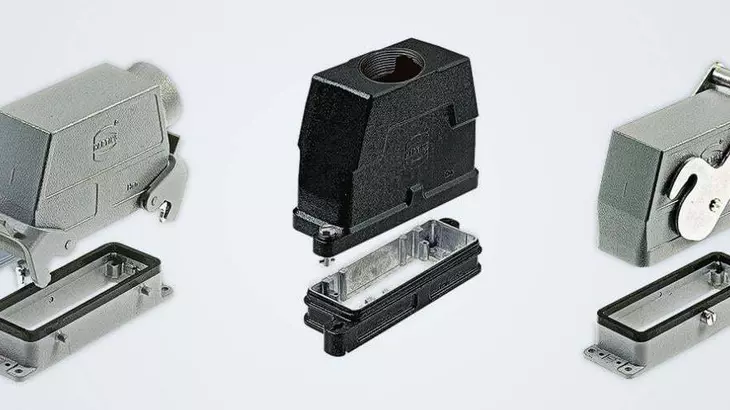

metal/plastic housing

angled/straight

screwable/locked

Coupling housing/special adapter shape

Pre-assembled connection cables on one or both ends

The contact and cable diameters increase with the voltage to be transmitted. Common upper voltage limits in energy distribution and in the transmission grid are 6 kV / 30 kV / 110 kV and 380 kV. More and more pluggable voltage levels are currently emerging, particularly in the renewable energy sector, i.e. between 6 kV and 30 kV. Because the systems are modular and need to be set up quickly, the use of connectors is essential. This applies to systems for hydrogen production, wind energy, photovoltaics and fuel cells.

The shapes of the connectors depend on the required current carrying capacity and on safety aspects during installation, operation and when plugging and unplugging.

High voltages and relatively low rated currents are required for test systems in materials and testing technology, micro and semiconductor electronics or medical and biotechnology. Fine, elongated, pointed contacts placed in robust plastic, metal or rubber insulating bodies are sufficient here.

High rated currents and high voltages are required in power distribution. Specialised tools and specifically trained personnel are required to connect or disconnect prefabricated transmission cables and accessories for the HV level. To increase operator safety and electromagnetic compatibility, thick insulators and solid rubber or plastic sheaths are placed around conductors and contacts. This makes the use of connectors a little complicated, but it is still possible and in demand to utilise their advantages at these voltage levels.

How do high voltage connectors work?

Connectors separate and link electrical cables so that the flow of current can be interrupted at one point if necessary. Transmission takes place when the socket and pin are linked by positive locking. The electrons travel across the contact surfaces between the pin and socket. The cable is connected to the contact using screw, crimp or axial screw technology.

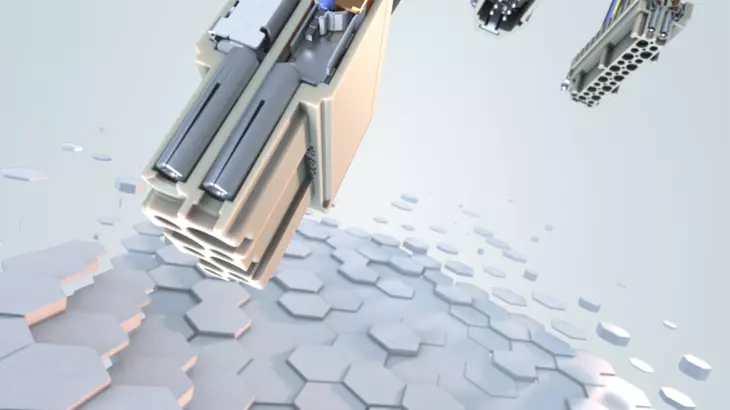

HV connectors differ according to the requirements of the application. If high currents and voltages need to be transmitted, large conductor cross-sections are required. Solid, turned cylindrical contacts made of aluminium and/or copper are used as contacts - in straight or angled versions. To facilitate insertion and removal, the socket contacts are lined on the inside with inserted wire braids, grids or sleeves, which are applied to the pin contacts and ensure even contacting.

For HV transmission with relatively low currents, e.g. 30 A, circular connectors (e.g. M8, M12, M17 and also non-metric threads) are also used. These use robust plastic or metal housings, insulation bodies and contacts with medium or smaller diameters (customised or standard sizes down to D-Sub).

The housings of HV connectors are usually particularly robust. The material is die-cast aluminium, plastic or silicone rubber. Insulating bodies are made up of several shells in order to extend clearance and creepage distances and counteract heat development. Shielded versions are also protected by conductive material with a PE connection.

In various high-tech areas (e.g. in medical technology), narrow spring contact pins in metal or plastic sheathing are used as high-current contacts; the housings are fitted with bayonet, screw or shackle closures.

Who uses which HV connectors where?

Manufacturers of transport technology use HV connectors in the downstream stages to the current collector, after the transformer, for the distribution of electrical energy from the locomotive to the carriages, which are pluggable and expandable. Powerful components such as transformers or drives must also be supplied with power, signals and data and integrated into the train infrastructure. Cable systems for power distribution in the underfloor area are also equipped with connectors. In the railway sector, the upper limit for pluggable power transformers is currently around 4.5 kV AC. For the transmission of direct current, the upper limits are approx. 50% higher.

In the field of power transmission technology, pre-assembled cables with HV connectors are used, which are shielded and screwable. Some of them can transmit several hundred kV. They have been optimised for connecting switchgear and transformers to the supply network (IEC, IEEE, GB/T type). Other areas of application include substations, underground cabling, renewable energy systems, mining and railway technology as well as offshore platforms (oil/natural gas).

What are the advantages of HV connectors? Why do you need them?

Connectors help to speed up and standardise the installation of transport technology and energy infrastructure. Connectors speed things up because they enable more pre-installations, make processes repeatable and ensure quality. They speed up on-site installation compared to hardwiring. In many cases, it is no longer necessary to employ electricians on site. Installation can become more cost-effective.

What should I look out for when choosing?

High-voltage connectors are often used outdoors or in harsh environmental conditions, so make sure that the components have a minimal tendency to corrode and adequate IP protection.

High voltages pose a danger to the operator's life. Therefore, in the interests of the operator's safety, ensure that the contacts are safe to touch.

The maximum current carrying capacity of the contacts depends on the respective application; adjust the cable and contact cross-sections accordingly.

With HV connectors, high clearance and creepage distances must be maintained and the contacts must be integrated so that they are safe to touch and to ensure safe operation or handling.

You should rely only on tested and certified material for your type of application.