Semiconductor Tool Connectivity

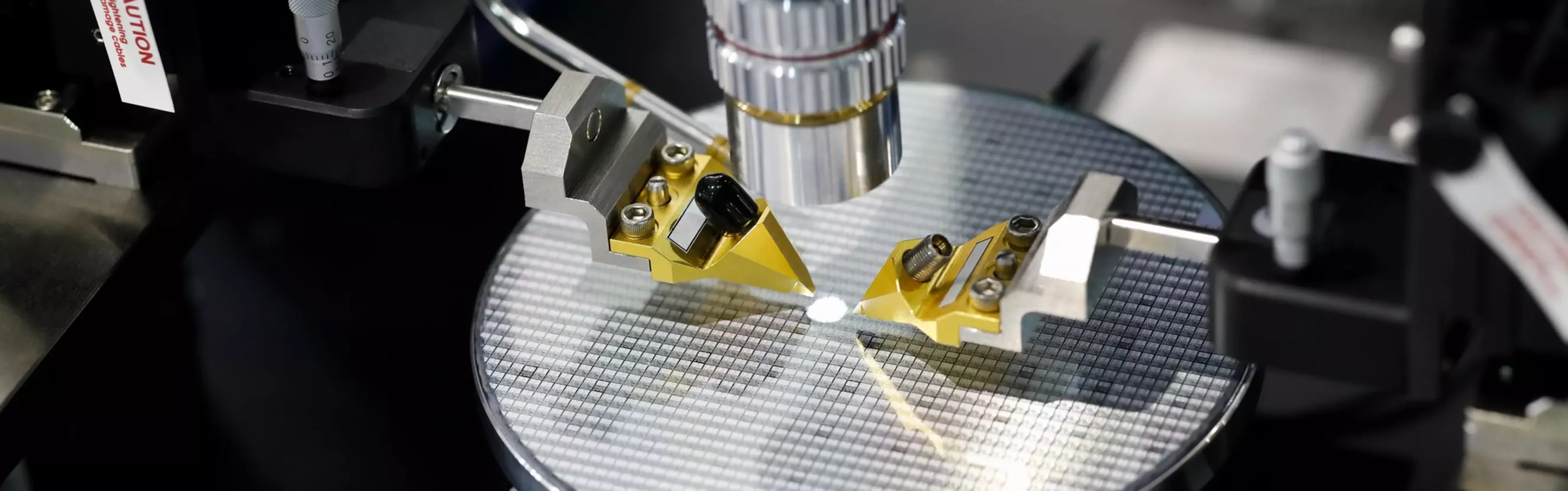

Answer the call for miniaturization and improve the design of your semiconductor manufacturing equipment.

Compact, efficient semiconductor equipment design

The push for miniaturization is felt in the semiconductor tool manufacturing industry more than most industries. Engineers are constantly asked to fit more functionality into less space, and with parts that are easy to scale, long-lasting, reliable, and rugged. This combination of challenges can seem daunting.

This is why semiconductor equipment manufacturers turn to HARTING’s full solutions portfolio to achieve true miniaturization, with components that are 30-70% smaller than other connectors. Merge power, signals, data, and even pneumatics into a single modular connector. Or lean on Power-Over-Ethernet options to maximize connectivity capabilities.

MINI & MIGHTY SOLUTIONS

Many connectors, infinite possibilities.

The effectiveness of your semiconductor manufacturing equipment relies on dependable connectivity, for power, data, and/or signal relays. With a broad range of connectivity solutions, you’ll be sure to find what you need for the designs of today and innovations of tomorrow.

✓ Modularity allows for multiple connection types and sizes within one compact port

✓ One connector can do multiple jobs – data and power in one connection

✓ Breadth of connector portfolio covers various application needs

✓ Custom product design services available to meet unique customer needs

ENGINEER COLLABORATION

Tools and resources to equip your teams at each stage of development.

Extend your engineering teams with personalized, expert technical assistance from concept to production. Optionally, collaborative Opportunity Audits with HARTING’s experienced engineers can introduce fresh perspectives on existing designs and operations.

✓ Streamline prototyping, team collaboration, and design

✓ Easily share designs, files, and product configurations with colleagues

✓ Uncover areas for connectivity improvements, design innovations, and procurement efficiencies

✓ Quicker problem identification and solution development

✓ Customized information portals, virtual Tech Day sessions, and dedicated technical support

STREAMLINED MANUFACTURING & PROCUREMENT

Benefit from in-region and global production operations.

When it comes to delivery, there's zero tolerance for excessive lead times, no matter the circumstances. For both engineers and procurement professionals, a reliable, streamlined supply chain that reduces decision fatigue is essential.

✓ Simplified procurement and deliverability with one partner

✓ Leverage supply chain, manufacturing, and product delivery efficiencies

✓ Scale operations and support through multiple manufacturing facilities across the globe

✓ Take advantage of CHiPS Act incentives and support China +1 inititatives

Featured semiconductor manufacturing components

Proud Member of SEMI

The leading semiconductor industry association

SEMI is the only global industry association providing a platform to unite the semiconductor ecosystem with the broader electronics manufacturing and design supply chain.

HARTING is a member of this vibrant community of over 3,000 worldwide members, participating in industry events, standards programs, and community thought leadership.

Connect With Our Experts

Our team of Technical Application Consultants is available!

If you’ve got questions about connectorization or our solutions' capabilities, our experts are ready to answer them.

Contact our in-house engineers for technical guidance or design help and let us be the connector specialist extension of your team.

HARTING Product Configurator

Design your next connector, then download documentation in various formats — 3D files for CAD, Bill of Materials (BOM) — for easy collaboration and hassle-free ordering.