Industrial Ethernet solutions

Ethernet is the first choice when it comes to data transfer in industrial applications. Learn more about the HARTING Industrial Ethernet portfolio.

Ethernet is becoming the universal communication protocol in more and more areas. Discover the HARTING range of products for Industrial Ethernet connectivity and cabling.

Jump to series

Complete Ethernet connectivity PDF guide

Diese übersichtliche Auswahlhilfe im PDF-Format gibt Ihnen einen vollständigen Überblick über das umfangreiche Angebot an HARTING-Produkten auf dem weitreichenden Markt der Industrial Ethernet Connectivity.

More solutions and resources

Learn from our product managers

Spotlight on harsh enviroments: challenges to pass for industrial ethernet connectivity

Industrial Ethernet Installations are deploeyed almost everywhere. The connectivity has to guarantee a save and reliable transmission even under harshest industrial evironments. Joachim Finke and Heiko Meier will give an overview on the specific challenges to pass.

High performance and innovative ethernet PCB connectivity

Miniaturized, compact & powerful! The innovative PCB connectivity of HARTING enables new possibilities in device design. Learn more from the HARTING Technology Group Product Managers Nikolaj Ponomarjow, Marian Dümke and Maximilian Rohrer.

RJ Industrial® Ethernet interface

RJ 45 for harsh industrial enviroments: Our new RJ Industrial® is absolutely robust and reliable and in the 'Multifeature' edtion with integrated cutting tools for quick and easy assembly. This can save you up to 25 % time when installing the Ethernet infrastructure.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

ix Industrial® - miniaturized interface for industrial ethernet

Due to the 70% smaller device socket compared to the well-known RJ45, the ix Industrial® offers the perfect standardized interface for Gigabit Ethernet. In combination with excellent shielding, robustness and outstanding performance the ix Industrial® is the perfect choice for miniaturized devices.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

T1 Industrial - Single Pair Ethernet

Transmission of Ethernet via just one single pair of copper wires. SPE is the perfect technology to connect field devices to the Ethernet network. Single Pair Ethernet technology is fast, space-saving, cost-efficient and ready to implement. The equipping of simple sensors, cameras and more with Ethernet interfaces positions SPE as the driver of topics like Integrated Industry and IIoT.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

preLink®

The preLink® system is an all-purpose, quick & easy cabling solution for industry, building automation and IT. It is also a solution that can be used with equal efficiency for all applications.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

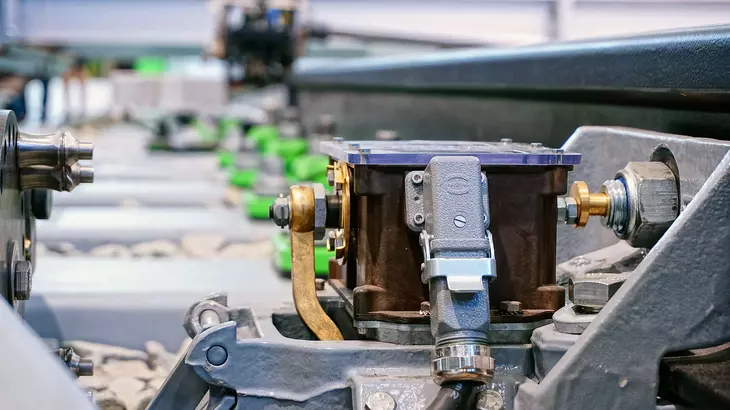

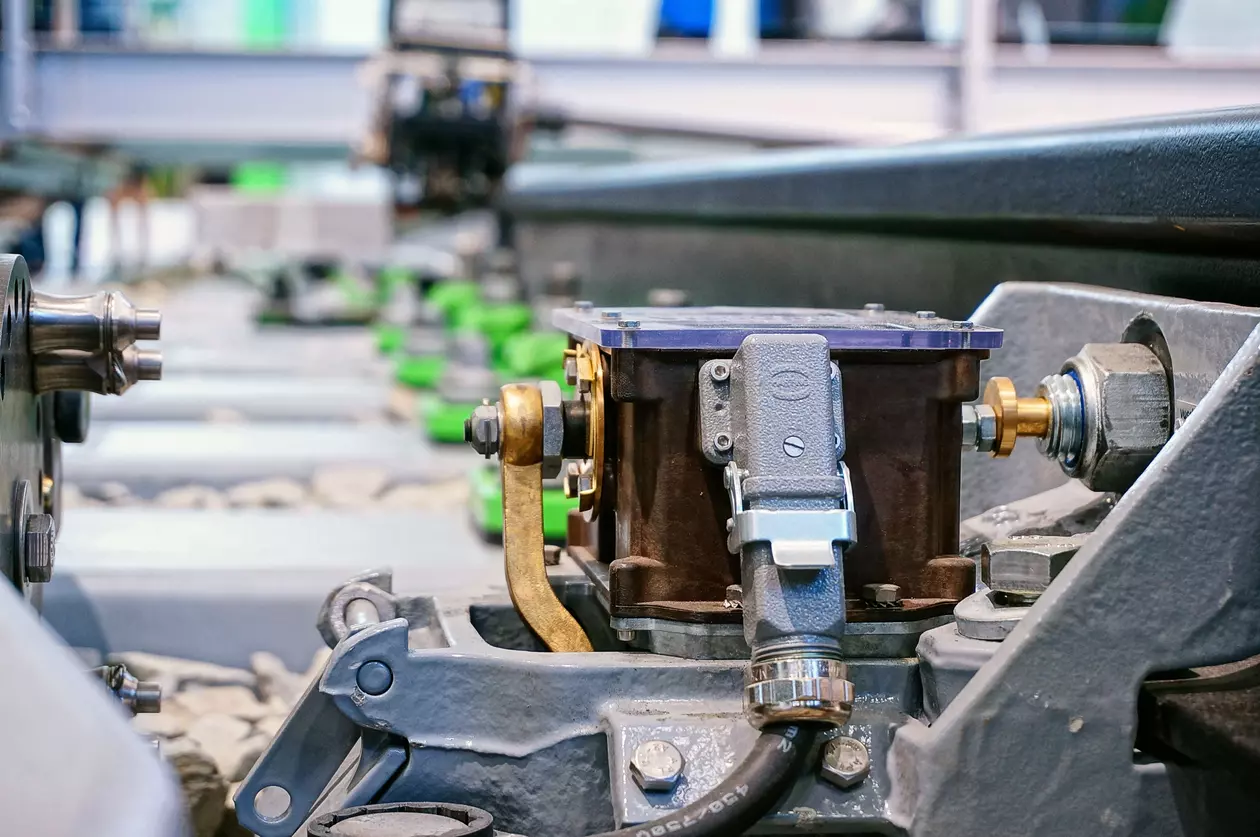

Circular connector M12 and M8

M8 and M12 interfaces combine three important advantages in industrial ethernet applications over the familiar RJ interface: a high IP degree of protection , very low space requirements , and a vibration-proof male/female contact system. Used in industrial building cabling, machinery construction, particularly in railway applications.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

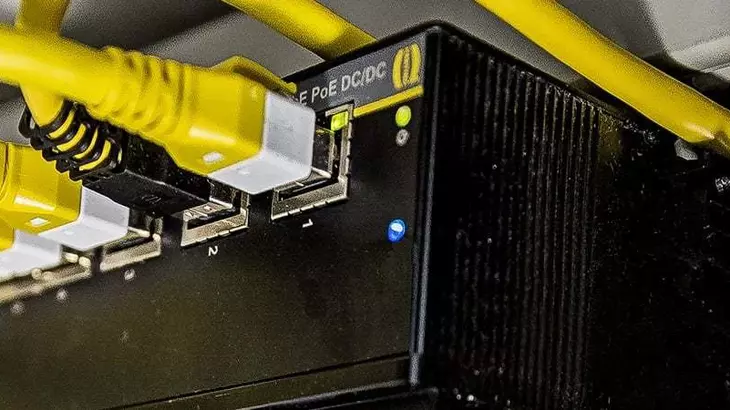

Industrial Ethernet Switches

The unmanaged Ethernet switches from the Ha-VIS eCon series now offer you further new models for an efficient setup and expansion of your Ethernet networks.

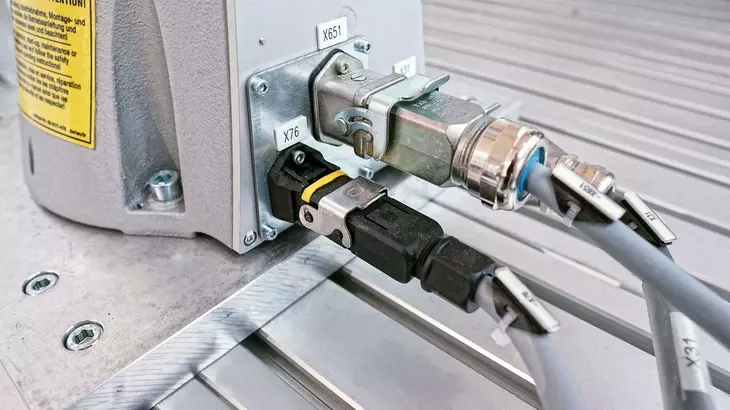

Han-Modular® - The market standard for modular industrial connectors

The Han-Modular® series is designed for combining power, data and signals in one connector. The multifaceted system of inserts, contacts, frames, hoods and housings as well as accessories fulfils individual customer requirements. The customer can choose between more than 100 different connector modules.

These are suitable for different transmission media and cover various termination techniques but also several solutions for data transmission (e.g. Han-Quintax® (cat 5), Han Megabit Module (2 x cat 5) and the Han Gigabit Module (cat 6a and cat 8.2)). The patented Han-Modular® hinged frame enables the configuration of all modules in the well-accepted Han® hoods and housings for all kinds of harsh environments.

Han® 1A - Compact, robust and versatile

For the first time, HARTING's Han® 1A offers a compact, affordable connector, which can be used for controllers, small drives and control cabinets, and can also be installed in the field. Within this very compact and cost-optimised product family HARTING offers now M12 D-coded and M12 X-coded inserts for different application fields.

Han® 3A - Compact connector for harsh environments

For strength and versatility, the Han® 3A industrial connector is used and recognized in the fields of machinery, robotics, transport and energy. You will find a version to suit whatever your needs for use in harsh industrial environments. Han® 3 A RJ45 contact inserts are available for different Ethernet transmission rates for all application types.

What is Ethernet and Industrial Ethernet?

By using Ethernet as a universal communication protocol, the vision of a uniform protocol standard for communication from the cloud to every sensor is manifesting itself - and the IIoT is becoming more and more of a reality.

But what is Ethernet, what is behind it and what are the special features of the use of Ethernet in industry. Learn more about Ethernet in the following paragraphs.

The beginning - from Hawaii to the whole world

In the early 1970s, ALOHAnet, the world's first radio data network, began in the Hawaiian Islands. In 1970, University of Honolulu professor Norman Abramson was looking for a cheap communication solution for the university's various locations on neighbouring islands.

This first protocol, which fired data packets over two frequency bands at random in order to avoid collisions, comprised the basis for what would later become Ethernet. At that time, few people could have imagined how this development, dubbed ALOHAnet, would one day form the basis of communication for international industrial production. Today, industrial production is no longer conceivable without the ubiquitous Ethernet. The requirements for data transmission in automation environments are steadily increasing and are quantitatively reflected in the number of installed Ethernet nodes. Today, Ethernet with its Industrial Ethernet variants has become the most widely used communication standard in industrial plants - and the trend continues to rise. This makes the reliable infrastructure of interfaces and cabling even more important.

Ethernet is turning into the IIoT

IoT – the Internet of Things – describes the networking of virtual and real physical objects in order to make them interact using information and communication technologies. Objects in our daily lives acquire digital capabilities, and hence become real physical objects that can also participate in digital networks. This process also takes place in industrial applications, where it is called the Industrial Internet of Things (IIoT).

More and more industrial components are also becoming smart and intelligent participants. However, they are no longer limited to the upper levels of internal company networks as they once were. Ethernet protocols have been increasingly connected to cloud systems in recent years, while something is also starting to happen at the field level. Here, Single Pair Ethernet (SPE for short) is the new "physical layer" that covers the last mile to bring Ethernet right to the sensors.

The increased collection, evaluation and use of data creates the need for more powerful infrastructure. At the same time, this infrastructure is expected to take up less space and use less resources. Efficiency is the key word here, as more and more sensors with their increasing bandwidth requirements become network participants. New hardware technologies are required.

Automation and IT merge into automation

Simultaneously, automation environments continue to join together with the previously separate IT world. The thrust is to process increased data rates from all areas of the company in a practical manner and use these in clever algorithms. The aim of automation has always been to increase flexibility and productivity. Connecting all industrial machines with each other and with IT enables the data obtained from the machines to be visualised while also enabling predictions to be made using clever evaluations. Where do I need to tweak my process? Where is optimisation potential hidden?

IT-supported data evaluation opens up completely new possibilities for optimisation. The digitalisation of the field level also brings about completely new business models or services that were previously unthinkable. Pay-per-part models or the software-based activation of additional functions in machinery are just two examples.

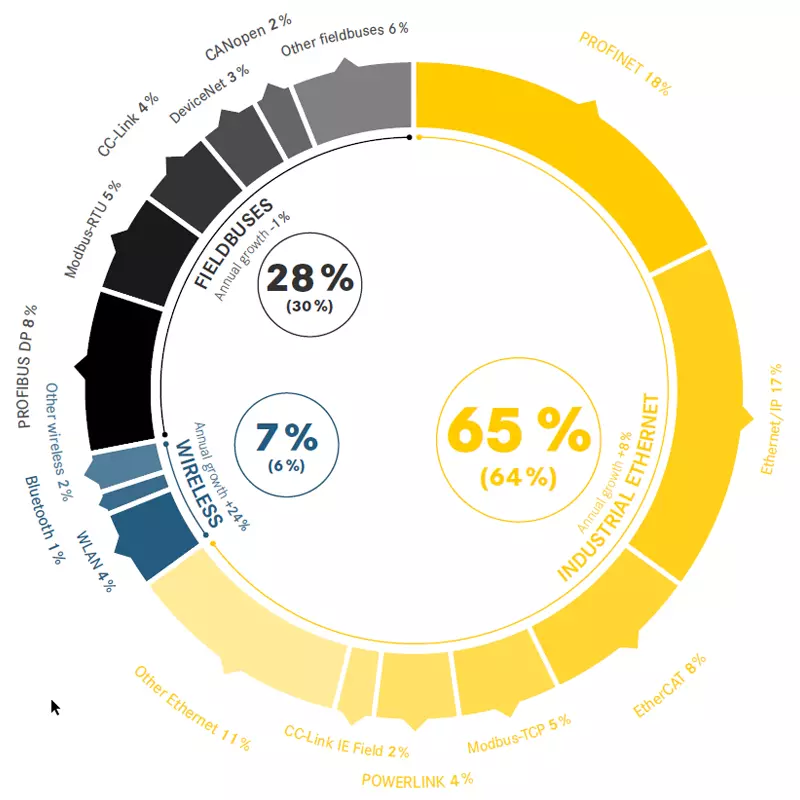

Above and beyond this, the operators of plants can keep an eye on their processes worldwide. For all of these developments, Ethernet protocol is the unifying language that enables this convergence. It also becomes clear just how important it is to carry out this fusion consistently in every detail. Ethernet from the cloud to the sensor - this is how to implement real IIoT. The development away from analogue systems and fieldbuses towards Ethernet protocols comes up regularly in the annually published studies of the HMS Industrial Network. These studies show the market distribution of new communication nodes in industrial networks. While Ethernet protocols had an overall share of 38% in 2016, just five years ago, this has now grown to 65% in 2021. Meanwhile, the total share of fieldbus systems has shrunk by 30 %.

The trend towards a uniform protocol for all business areas continues unabated. But how has this affected your choice of infrastructure and interfaces? Which connector is suitable for which application? When is an industry-grade solution necessary? Which solutions are perfect today but could be obsolete tomorrow?

The key medium - cuprum

Cuprum is derived from the Greek word Cyprium and means something like "ore from the Greek island of Cyprus". According to tradition, this is where it was first extracted and where it got its name. As an excellent electrical conductor available in sufficiently quantities, it is the set standard for the transmission of currents of all kinds.

This is also the case in data cables for Ethernet networks. Over the decades, new standards have been set in transmission rates that were previously considered impossible. Clever twisting of wire pairs and efficient shielding concepts currently make transmission rates of up to 40 Gbit/s possible, which corresponds to the Cat.8.1/8.2 standard. What you find here are four pairs of stranded copper wires, which add up to a total of eight wires that transmit data. This divides the data stream into several paths. The previously mentioned stranding and shielding make high frequencies possible, however the frequencies currently possible are or were exhausted. The latest developments in single-pair Ethernet are breaking new ground in this area, but more on that later.

Alternative communication medium

It has been repeatedly said that copper as a communication medium will be replaced by alternative transmission options in the foreseeable future. But is copper really loosing its position or rather set to become the basis for all IIoT plans? Electrical transmission is the common factor to all copper-based solutions. This sets physical limits on the usable frequencies and the transmission length. 1/10/25/40 Gbit/s over 100 metres is the known limit for Ethernet via copper cable.

To circumvent this limitation with respect to both transmission rate and transmission length, and also to connect mobile systems with Ethernet, fibre-optic conductors are now used just as much as wireless radio systems. For some years now, fibre optics and WLAN have been considered to be the future communication medium that will overtake the traditional cable. But is this really the case?

Admittedly: With fibre optic cables, high data rates can be transmitted over distances of many kilometres, and that without complex shielding to control EMC. WLAN combines gigabit transmission with being able to move independent of fixed cabling. If I have already installed a WLAN access point, new devices are quickly connected wirelessly. Until then, however, installation of the access point is costly and this also must have a cable connection. Unfortunately, the user must accept a few decisive disadvantages when using these technologies. Optical fibres must be connected under very clean conditions to avoid signal attenuation due to contamination. Likewise, no supply voltages can be transmitted in addition to the data. A device still needs additional copper cabling for the power supply.

The same applies to WLAN devices. Mobile solutions often rely on rechargeable batteries or a power supply connected by copper cable, which ultimately negates the mobility advantage. Another issue is the environmental impact of rechargeable batteries, which is increasingly coming into focus today. Furthermore, a number of further issues must be considered: real-time transmission is not guaranteed and the data rate is reduced depending on the location and number of recipients. How secure is my data when sent wirelessly and how high is the radiation exposure in sensitive areas? These are issues that can be safely neglected with classic copper cable. Ethernet over four or eight wires offers up to 100 watts of supply power at the device via Power over Ethernet (PoE) and in many cases makes an additional power supply unnecessary. If the application allows it, a single-cable solution is always preferred. This feature comes into its own especially in the cramped conditions of the field level. During the course of development of IIoT, more and more smart sensors and other participants are being relocated into machines and require the space-saving supply of data and power here. One new development i

THREE STEPS TO THE RIGHT ETHERNET INTERFACE

1. WHAT SPEED IS REQUIRED?

What data rate does the application require. Is Fast Ethernet sufficient or is Gigabit Ethernet required? This makes it necessary to design the connection technology and cabling either in two pairs for Fast Ethernet (up to 100 Mbit/s) or in four pairs for Gigabit Ethernet.

EXAMPLE:

Compact vision sensor with PROFINET conformity

These vision sensors deliver high-resolution images and therefore the data interface must be designed for Gigabit Ethernet. Robustness and a small installation space are further requirements. The ix Industrial® interface is suitable for simple IP20 applications or the M12 X-coded as a waterproof and dustproof IP65/67 interface. Both interfaces are also PROFINET-compliant.

2. WHAT ARE THE ENVIRONMENTAL REQUIREMENTS?

In which environment should the application be used? The environmental requirements below are relevant for the selection of the design and these requirements should be considered:

• Degree of protection (IP20 or IP65/67)

• Temperature range

• Vibration and shock resistance

• Climatic and possibly also chemical resistance

EXAMPLE:

Data interfaces on robots in automobile manufacturing

Very robust and easily replaceable interfaces are required in this environment, as the cable packages wear out over their service life due to the permanent bending and torsional stress caused by the rapid movement of the robots. The Han® PushPull variant 14 in the metal version is perfect for this. Thanks to the PushPull locking mechanism, the cable packages can be replaced very quickly, minimising the downtimes. In addition, this design is available with RJ45 or optical data containers as well as with signals and power. In other words, this makes it the ideal interface for the lifelines of data, power & signals. Moreover, the interface is AIDA and PROFINET compliant.

3. WHAT IS THE APPLICATION?

Which applications will the unit be used with? Are there specifications from user organisations such as the PNO for PROFINET, ODVA for Ethernet/IP, ETG for EtherCAT, VNO for Varan, to name a few? These considerations often also lead to the selection of a standardised Ethernet interface. The available size of the unit and the available installation space in the application also play a role.

EXAMPLE:

Mechanical and plant engineering

In this area, the extremely robust Han® connectors are the measure of all things and whether as Han® 3A, Han-Modular® or also in other designs such as the Han® F&B for the food and beverage industry, there are RJ45 or M12 D- or X-coded designs available that can also be used for different Industrial Ethernet protocols.