Products & Solutions

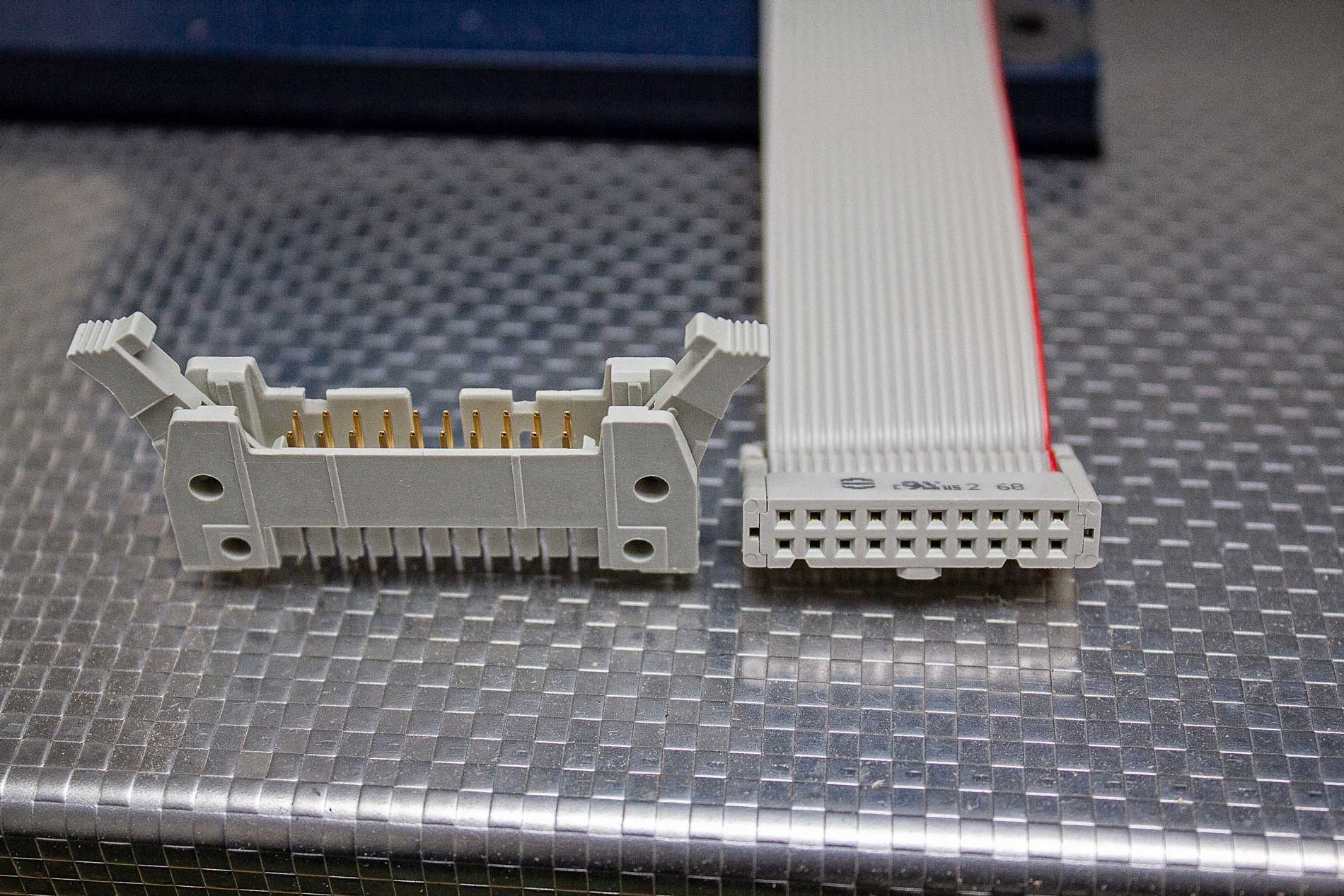

PCB connectors with ribbon cable

IDC insulation displacement connectors for ribbon cable

Insulation displacement connectors (IDC for short) are the ideal solution for device manufacturers if two or more PCBs are to be connected across longer distances. Where normal mezzanine or mother/daughter card arrangements are no longer sufficient, the IDC delivers reliable connectivity via ribbon cables.

HARTING offers a wide range of insulation displacement connector systems for ribbon cables that are designed for cable-to-board applications throughout a variety of sectors. HARTING tailors each IDC connector to your custom requirements, along with the appropriate cable type to simplify your installation and warehousing. The PCB connectors are available in various termination techniques: with solder termination (for manual, wave or reflow soldering) and press-fit technology. The different types have between 6 and 64 contacts. The cable connectors are suitable both for use within the device or for establishing connections between devices. Thus, IDC connectors provide a versatile solution suitable for any application.

Your benefits at a glance:

- Use ribbon cable to connect the PCB in the application

- Transmission of data and signals

- Gas-tight contact and connection to the electrical conductor using an insulation displacement connection

- Self-connecting, easy to assemble

- Connects several conductors simultaneously, in only one step or in only one press-fit process

- THT, THR and press-fit technology = variable PCB termination technology

1. Comprehensive portfolio

Both straight and 90° angled contacts are available. Stable locking levers are used for establishing secure connections to male or female connector strips. The female connectors are available optionally with strain relief.

2. Low-profile connectors

The low height of 9.4 mm allows you to save space. They also guarantee secure connections – even in confined spaces.

3. Through hole reflow soldering

Connectors suitable for through hole reflow soldering are made of temperature-resistant plastic (PCT).

4. Automatic assembly

Because of their tape & reel packaging, the IDC connectors can be integrated in automatic "Pick & Place" assembly processes and processed with other SMD components. This simplifies the PCB assembly process and reduces process costs.

5. Direct connection to the PCB

This cost-effective solution without plug-in complexity is made possible by directly connecting the ribbon cable to the circuit board. HARTING offers two-row or four-row PCB connectors for this purpose.