Products

Application examples

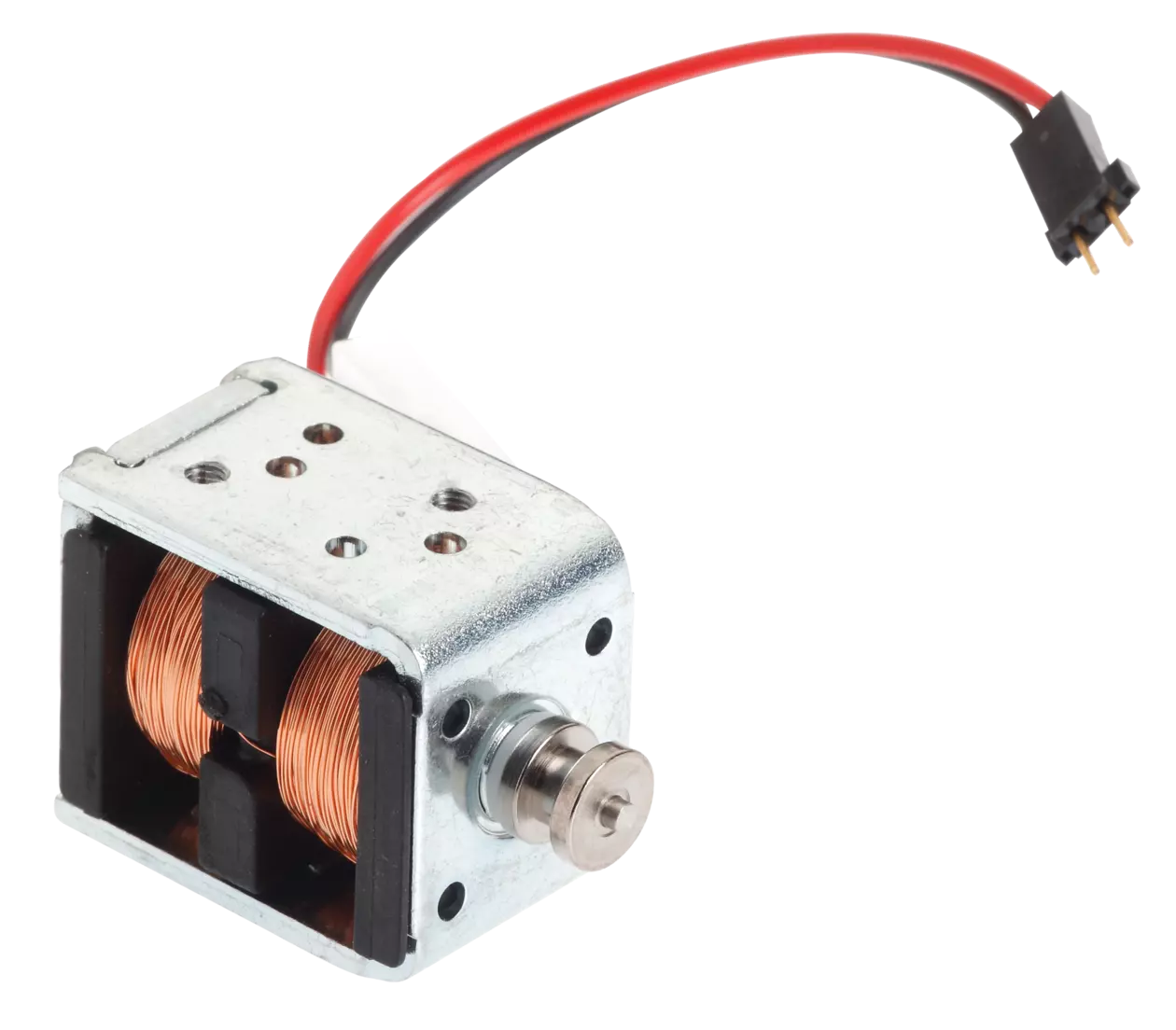

HARTING Automotive develops and produces customised solutions for automotive and industrial series-scale usage. Our products stand out for their most reliable functionality, highest quality and outstanding durability when used in ordinary or extraordinary solenoid applications.

Switching

Applications with switchable engine mounts, for example, have demanding environmental and acoustic requirements which must be met. Here, HARTING Automotive provides robust encapsulated and over-moulded systems with a wide variety of contacts, which can comply with different force-displacement requirements and have a long service life.

Our advantageous solenoid systems ensure improved driving comfort, vibration handling and noise characteristics.

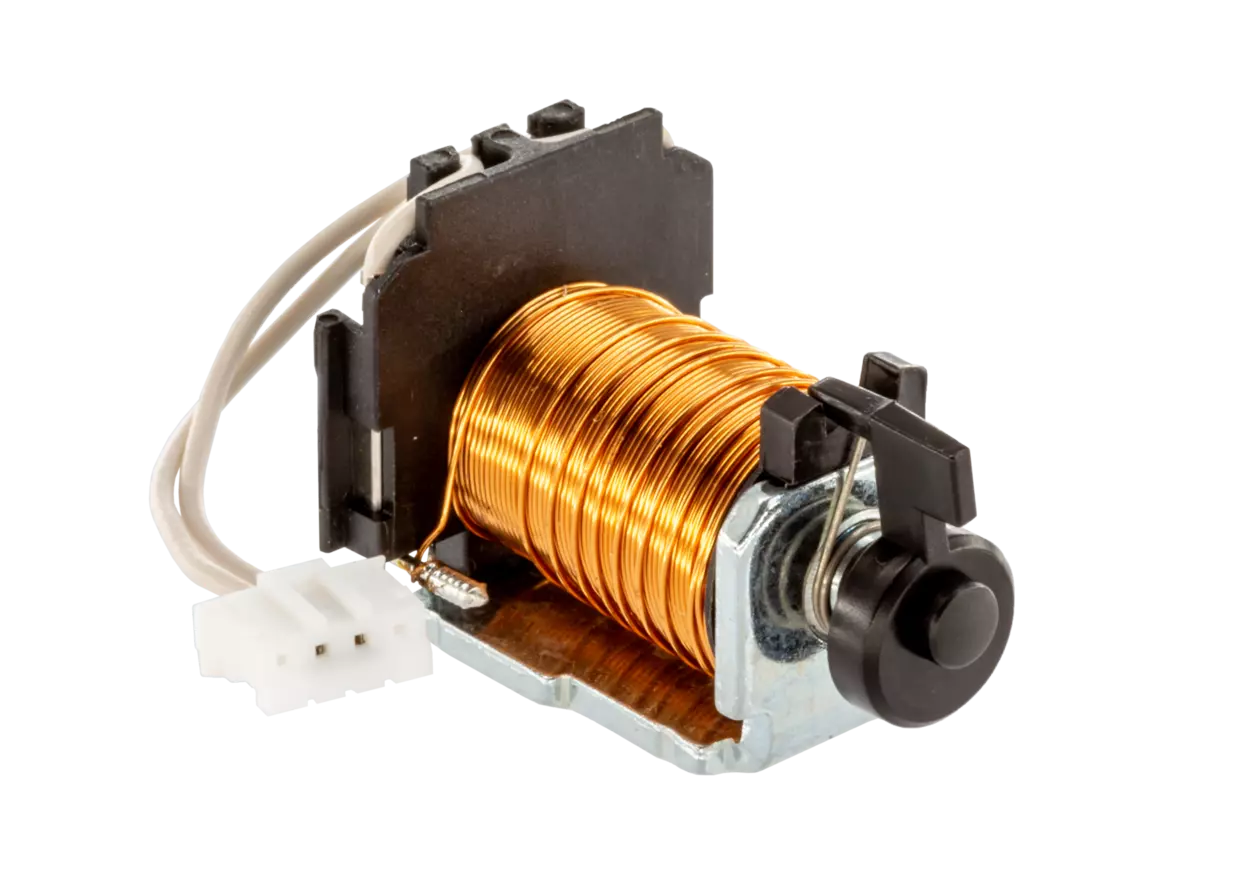

Triggering

For crash-active headrests: The reversible systems, which are manufactured in large series, provide safe, fast triggering. This capability ensures outstanding functional reliability and, at the same time, excellent robustness. The solenoid coil is completely enclosed by the housing within these closed systems.

The most demanding technical requirements for service life and protection class can then be reached. It is possible to implement a wide variety of contact options and force-displacement characteristics.

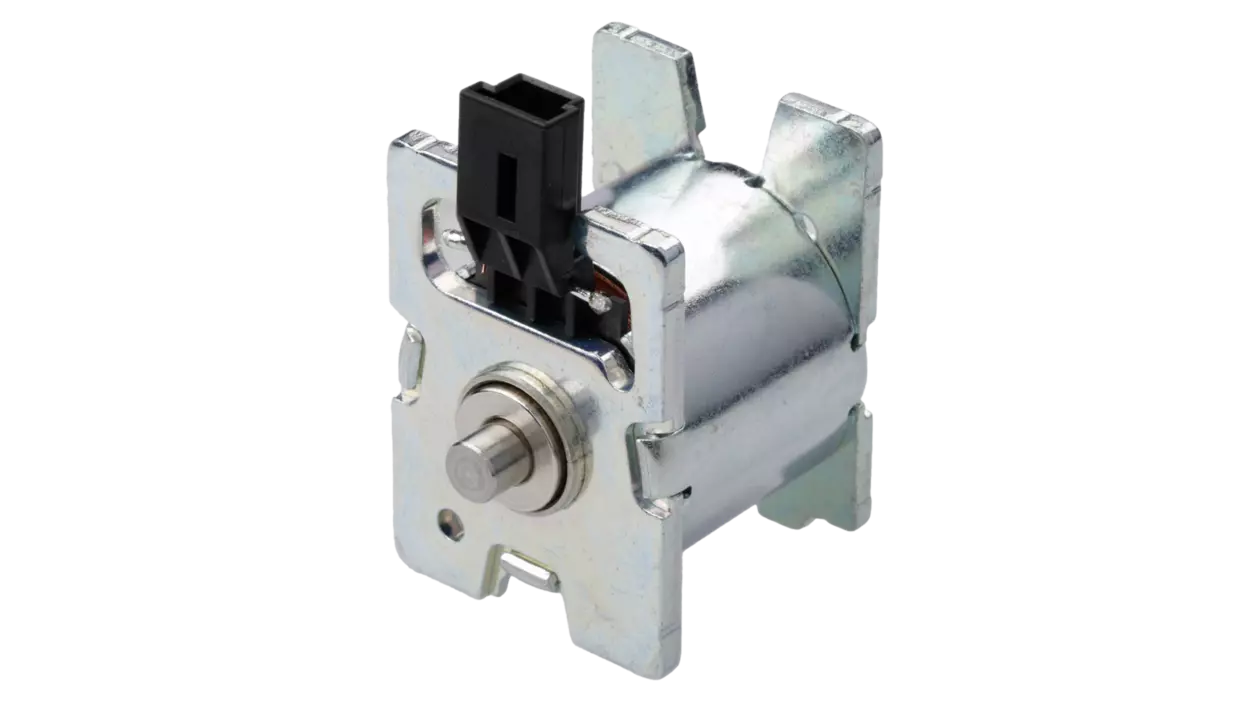

Locking

For automatic gearshifts: The acoustic requirements are particularly demanding for the interior of the vehicle. This is no problem for our solenoid systems. Various contact systems and force-displacement characteristics can be implemented depending on the particular application.

The solenoids lock themselves against high transverse forces; they can be implemented as open and closed systems.

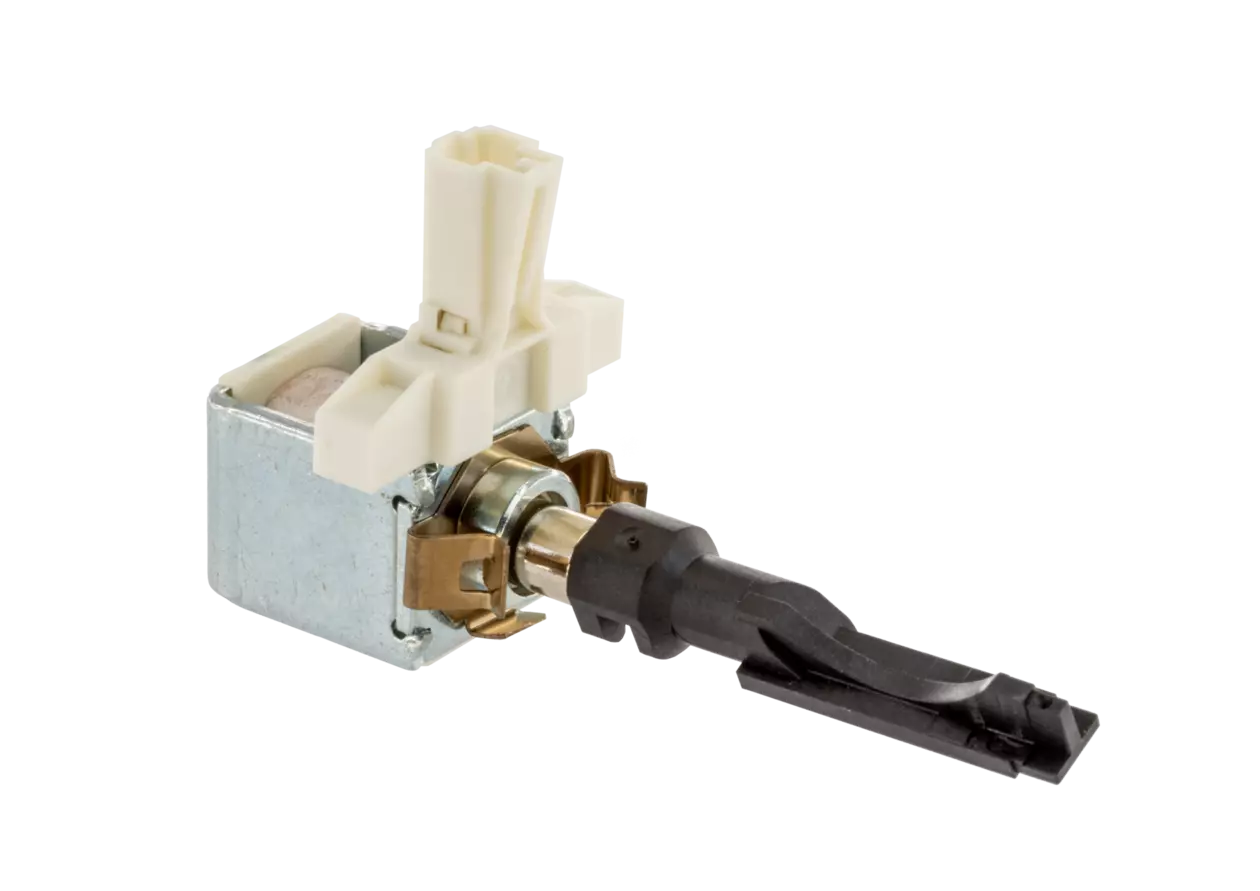

Interlocks

For ignition locks: The mono-stable and bi-stable systems meet very high acoustic requirements and enable a large number of switching cycles. The open lifting solenoids feature a magnetic body that only partially surrounds the solenoid coil.

Depending on the direction of the force output from the armature, a distinction is made between pulling and pushing operations. The linear movement is achieved from the stroke start to the stroke end using an electromagnetic force. The reset takes place using external forces or a spring.

Tactile feedback

For touchpads: HARTING Automotive's electromagnets can be used to achieve very precise force-displacement characteristics.

The electromagnetic actuators meet the highest demands on surface quality. They feature a fast go/stop response, low friction and enable a high frequency.

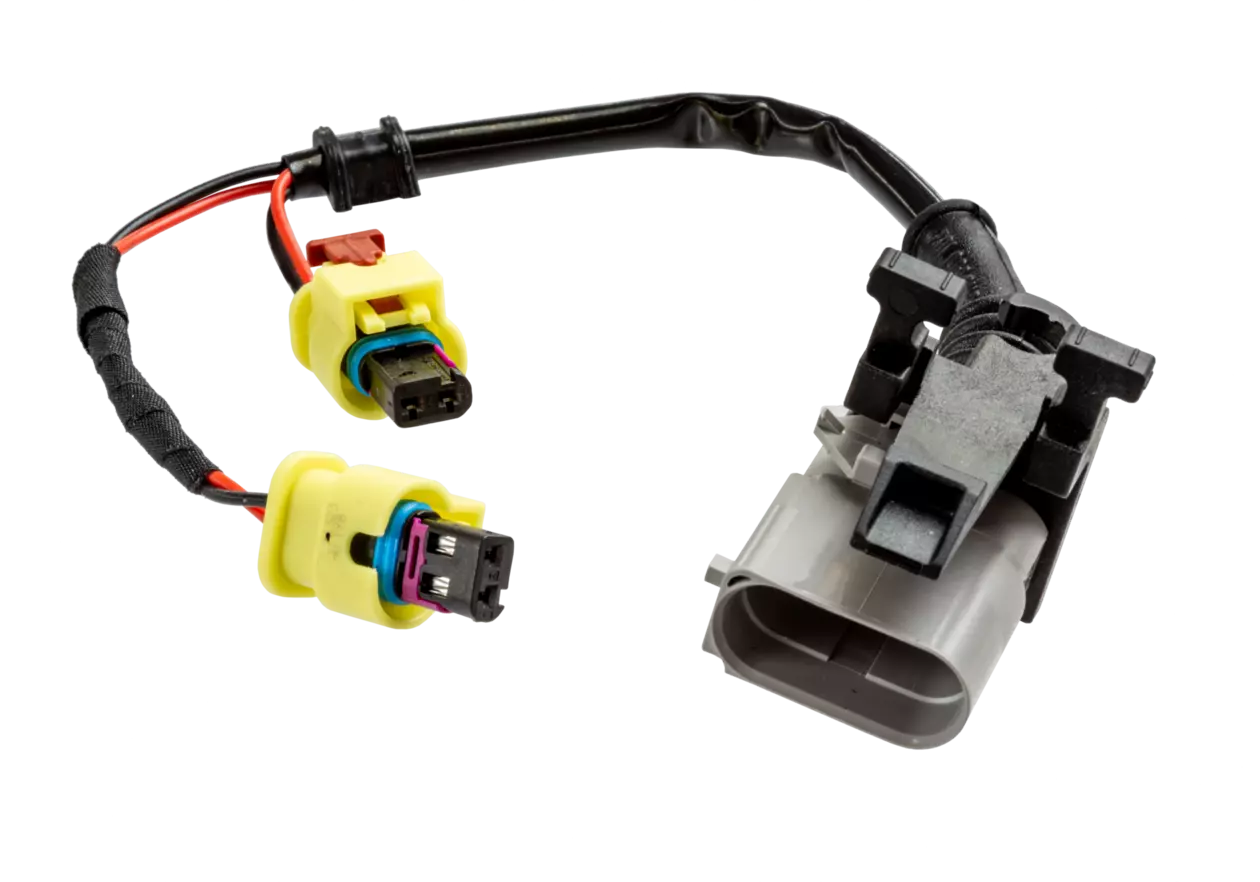

Customised cable assembly

For air suspensions: HARTING Automotive also assembles customised cable harnesses. If there are specific IP requirements, seals and gaskets can be designed and manufactured to match the customer's application. Any contacting requirements can be satisfied using our many fully automatic crimping machines.

Various industrial applications

Separating, lifting, lowering, closing, opening, holding, unlocking, locking: HARTING Automotive's customised electromagnetic systems stand out in a wide variety of applications and industrial sectors thanks to their outstanding conductivity and reliability.

Please contact us

Marie Klingenbeck

Position: Key Account Manager Solenoid Systems

- Company: HARTING Automotive

Key Account Manager