Commeo: Battery systems for the industry using Han® interfaces

In a joint project, Commeo and HARTING developed the appropriate interface. This interface connects the battery storage units with each other and with downstream units in a particularly efficient way. The solution was to integrate the Han-Modular® series modules with the Han® Docking Frame into a single unit. The new interface provides power and data to the storage units and controller. It is compact and can be quickly placed in the battery blocks. The housing for the connection modules is located inside the cube, while the mating face faces the rear side.

Interfaces transmitting data and power

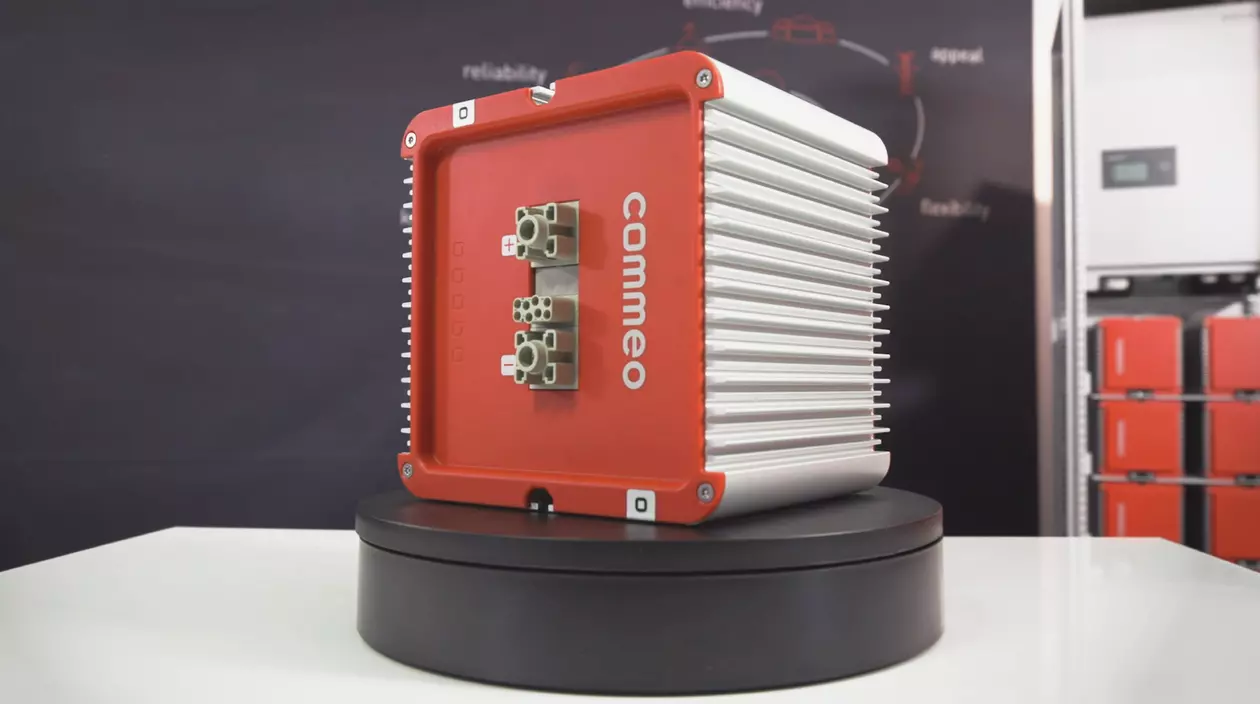

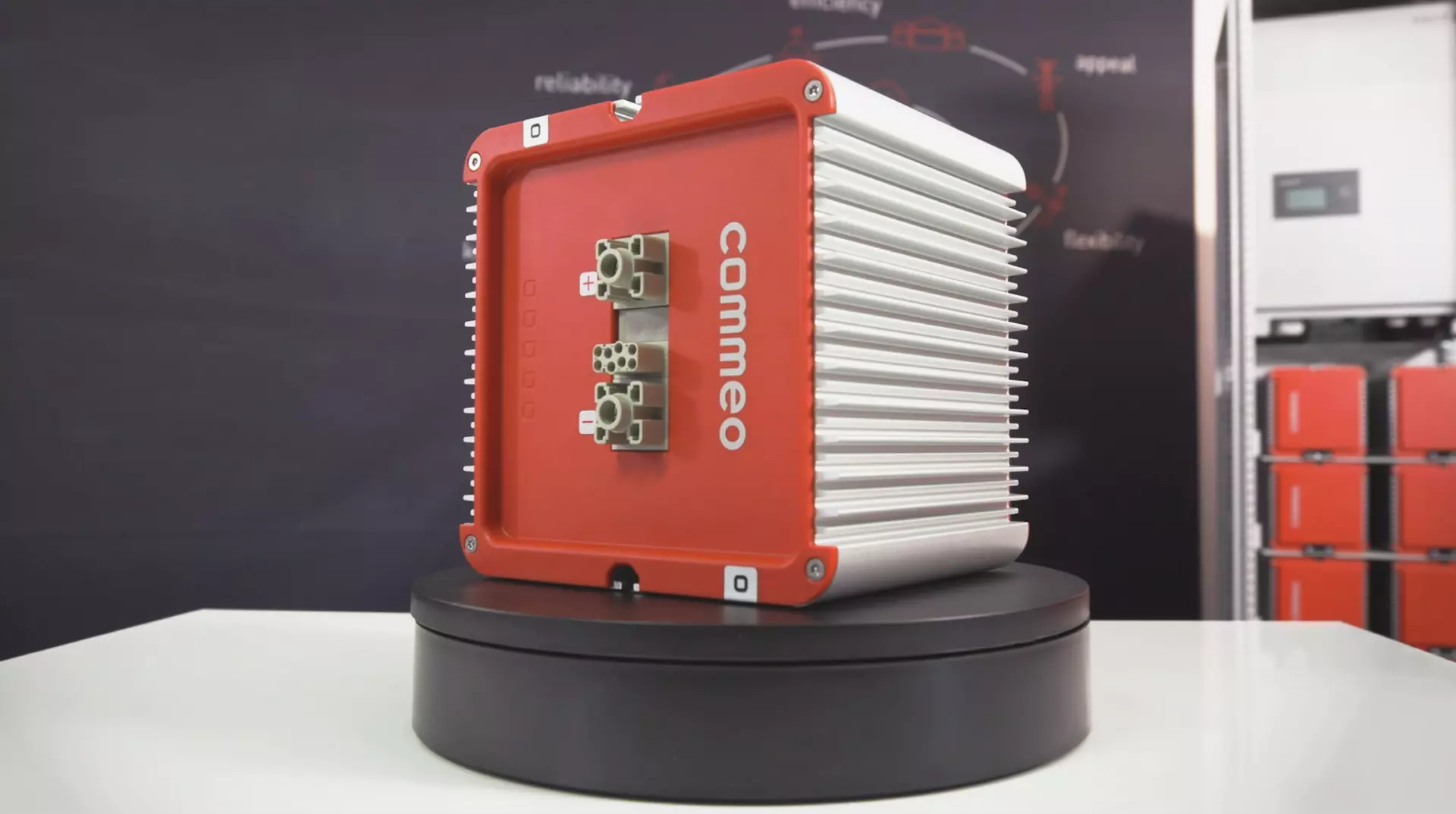

The system of Commeo consists of battery blocks that have a side length of more than 20 cm, containing multiple layers of lithiumion cells.

The blocks are responsive via a bus system and are aggregated into industrial battery storage cabinets. Each block has its own battery management system. A storage cabinet consist of 1.5 or 1.1 kWh units for configurations with voltages between 48 and 1000 V.

The modularity of the system makes it possible to precisely set the storage capacity in relation to system performance, which must be retrieved or replaced if required. The system can be easily scaled from a few kWh to 1 MWh. Subsequent corrections are possible.

Commeo Storage Block

Commeo: Battery systems for the industry using Han-Modular® interfaces

Commeo system buffers the grid

Commeo battery systems already today ensure the uninterrupted power supply of industrial parks or protect electric systems from damage caused by grid fluctuations.

They provide power compensation for renewable energy systems and serve as a buffer: If the voltage is too high, they charge current and cushion peak loads. In the event of a voltage drop, they can feed in their charge and support the grid.

Commeo's product is primarily aimed at machine and plant construction. “We want to become the first system provider for high-performance storage solutions in the world of automation, process industry and manufacturing operations,” says Managing Director Michael Schnakenberg. When the question of the right interface came up, HARTING was the clear favourite. “The recognition factor of HARTING connectors in the industrial environment is a fact. As soon as they see these interfaces our customers know that our batteries are compatible with their remaining facilities.”

Commeo back-up system for power supply. The modular interfaces of the units in combination with the docking frame enable installers to quickly and safely set up all required connections.

Customer benefits at a glance:

Reduced assembly time for modular storage cabinets due to interface combination of docking frame and modular plug connector

Leading centring system compensates tolerances and protects storage unit and interface

All requirements of a blind plug connector are fulfilled

Very robust design

Data/signal transmission and high power up to 200 A in one touch-proof interface

HARTING is immensely important to us because we can rely on the company‘s many years of experience in the field of connectors and power distribution. We get very high performance out of our modules, and we need a competent partner for this, who stands by our side. With the help of the products of HARTING we can ensure that the connection from our product to downstream products is always compatible.

Michael Schnakenberg

CEO, Commeo GmbH