Process

Together for your solenoid

Inquiry

Satisfying a wide range of customer requirements

HARTING Automotive develops and manufactures electromagnetic actuators exclusively to order – individually to meet your requirements. You define what our solenoid systems must do and you specify the framework conditions. A wide variety of requirements are taken into account. Your available installation space, the required ambient temperature, operating voltage, duty cycle, connection type and many other criteria are all factored into the design of the components.

Our sales department accepts your inquiry, collects all the necessary information in consultation with you, and passes the bundled information on to our specialist departments. Together with you, we discuss and work out any changes, adjustments and optimisations.

Development performance

Convincing development performance

Armed with your requirements and information, our specialists in the development department start designing the solenoid system on the basis of FEM calculations and simulations. When constructing the solenoids, the size, armature movement, duty cycle, holding force, type of contact, and many additional factors are taken into account. The basic diagram of the solenoid system is passed on to the construction department, where all individual parts are detailed and the assembly is worked out.

During this development process, we maintain the collaboration with you. This ensures that our solenoids are perfectly matched to the subsequent applications and that they work smoothly and trouble-free from the start.

Comprehensive construction of prototypes

Comprehensive construction of prototypes

HARTING Automotive has mastered the ABCs of prototyping – and in this case, that should be taken literally. Our prototype shop in Espelkamp is well equipped to produce A, B and C samples, to fully support the creation process of your solenoid.

In the first step, the first functional samples (A samples) are built in order to validate the simulation results and test the functionality of the components. In the subsequent (B sample) phase, we work closely with suppliers who build prototype tools for all the tool-related individual parts. Stamped, bent and turned parts can be manufactured in-house. The capabilities for series production of the components designed by us is checked using the B samples. After an acceptance, the series tools are commissioned and the entire production line is set up in Espelkamp in order to produce the C samples. This is the last step before series production at the final production site.

Laboratory tests

Wide range of laboratory tests

HARTING Automotive has its own solenoid laboratory in Espelkamp, in which the magnetic functions of the new systems are checked and measured. This includes force-displacement, 3D measurements and environmental simulations in climate chambers. The neighbouring, ultra-modern HARTING Quality and Technology Centre (HQT) offers more testing options. At the Centre, we can put the functionality of the products through their paces in salt spray, steam jet and vibration tests.

The laboratory tests are carried out in parallel to the various prototype phases. As part of the qualification process, we confirm that the current design of the prototype parts meets the customer's requirements. Adjustments and optimisations are made when necessary. Only then do the parts go into series production.

Focus on the customer

Customer-focused project management

A key factor in the success of project work at HARTING Automotive is customer-specific project management throughout all phases. From the time the order is placed until the end of the project, customers maintain a contact person in the sales department of HARTING Automotive who accompanies the entire project continuously. This contact guarantees the high quality of the workmanship until the product goes into series production. The project manager coordinates all the tasks of our specialist departments as well as the interfaces to the customers to ensure a functioning and efficient whole.

Our project management scrutinises all relevant factors – never in isolation, but always in coordination with all other factors. Regardless of whether it is development work, prototyping or laboratory testing – you can be sure that we will maintain high quality and keep deadlines.

Production

Leading expertise in manufacturing

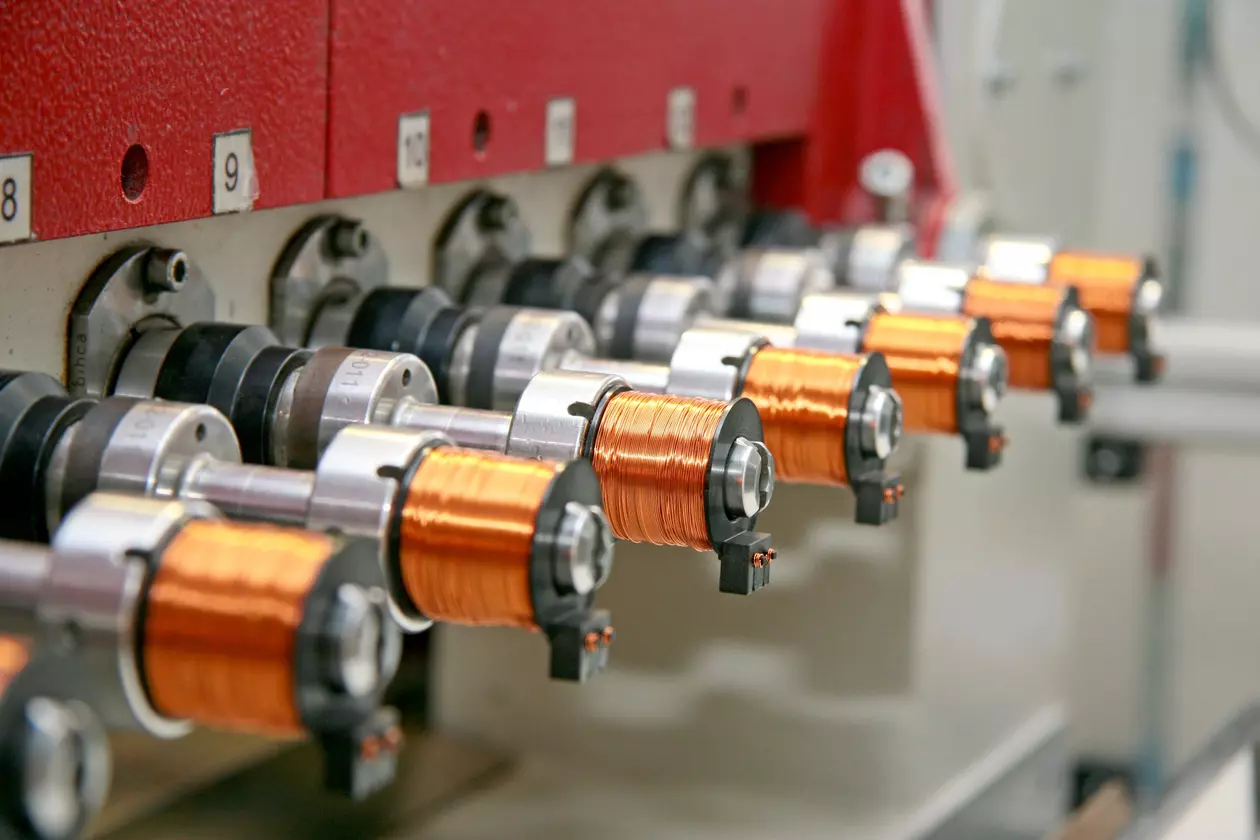

After the successful product qualification and the series approval by the customer, the new solenoid systems will be handed over for series production to our Romanian plants in Sibiu and Agnita. Our Romanian factories are now among the largest foreign production sites in the HARTING Group.

The electromagnetic actuators are manufactured in the assembly halls. These halls are equipped with state-of-the-art machines, systems and tools. The actuators are then delivered to customers worldwide. Our Romanian factories are equipped with high-performance technology such as fully automatic crimping machines and ultrasonic welding systems. They have extensive manufacturing expertise in winding coils, cutting, crimping and contacting cables, as well as in welding, potting and over-moulding.

Please contact us

Marie Klingenbeck

Position: Key Account Manager Solenoid Systems

- Company: HARTING Automotive

Key Account Manager