Knowledge about battery connectors

What are battery (pole) connectors?

Battery connectors are electrical components that accelerate the connection of storage modules to form more comprehensive energy storage systems (ESS). If necessary, the connections between the units can also be quickly disconnected again. The housings are designed in such a way that the positive and negative poles can be reliably distinguished by colour (e.g. red/black, orange/black). Solutions in which housings can be rotated 360 degrees when plugged in are helpful so that the cable runs between the individual batteries in the storage cabinet remain flexible.

What types of battery connectors are there?

Angled battery connectors for higher currents (approx. 100 to 450 A) that can be rotated 360 degrees even when mated

Straight screw or busbar contacts (often in a round housing) for front-side connection of the storage modules (all sizes)

Busbar connection terminals for the rear connection of battery storage modules to busbars

Two-pole (shrapnel) blade terminals for systems with lower current

How do battery storage connectors work?

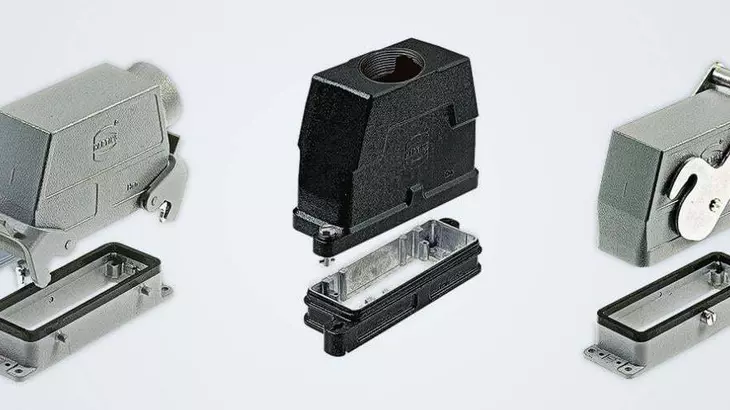

With the more powerful right-angle connectors and the straight pin contacts in the add-on housing on the device side, the contacts are designed to be safe to touch and have a screw contour with an M8 thread to attach them to the battery modules.

The female contact is crimped onto the cable, plugged into the hood, which is then mated with the male connector side and locked. The housing for the positive terminal can be red, brown, orange or mixed colours, while the variant for the negative terminal is usually black or blue. Both sides are also mechanically coded to prevent incorrect insertion.

Connectors for the rear connection of battery storage modules to a busbar facilitate the integration of the battery modules into larger energy storage systems. The mix-up-proof coded connectors are suitable for DC system voltages of up to 1,500 V and must be plugged to the power busbar at the rear of the storage units.

Who uses battery connectors where?

Battery storage connectors are suitable for the construction of storage systems in the context of uninterruptible power supplies for industrial plants as well as for a wide range of applications in renewable energy generation and storage: energy storage cabinets, photovoltaic systems, water-cooled inverters and much more.

Operators of larger storage units can use their battery storage modules from a suitable power level. Each modular storage system or storage cabinet contains a battery management module.These units also need to be connected to form a control line. Here too, entire battery strings can be managed using the bulkhead mounted housing including a busbar contact. The decentralised battery management systems transmit status messages to the higher-level system controller.

What are the advantages of battery storage connectors?

Battery connectors are characterised by their compact design and high current carrying capacity.

Quick connect: direct connection of the battery modules to the busbar in the rack (shortens installation/commissioning time)

Safe installation: battery connectors are touch-safe even in unmated condition (no need for highly qualified technicians)

Wide range of applications: modular design enables different current ratings

Slide-in system with integrated interface: no wiring required during installation

Reduction of maintenance & repairs times

More sophisticated connectors can be rotated 360°, even in mated condition*

*Notice: This feature guarantees flexibility that can pay off. If a cell in a storage module exhibits a drop in performance, it can be switched off and replaced via the respective management system. The interfaces of the neighbouring modules are turned aside when locked to create space for replacement. It is not necessary to interrupt the storage functions of the unaffected modules.

What do I need to consider when making a selection?

The voltage and current levels of the planned energy storage system and its individual modules must be complied with.

For applications in the railway sector, compliance with the relevant railway standards must be ensured, particularly with regard to shock and vibration safety (DIN EN 61373). For applications in the e-mobility sector, refer to SAE/USCAR-2 item 5.4.6 class V2 for the shock and vibration requirement.

For optimum operator safety, it is also essential to only use battery connectors with touch-safe contacts.