Easily bridging contacts in inserts of industrial connectors

Cutting installation time by up to 50% and multiplication of potentials using the tool-less rapid termination technology of the Han® ES Press.

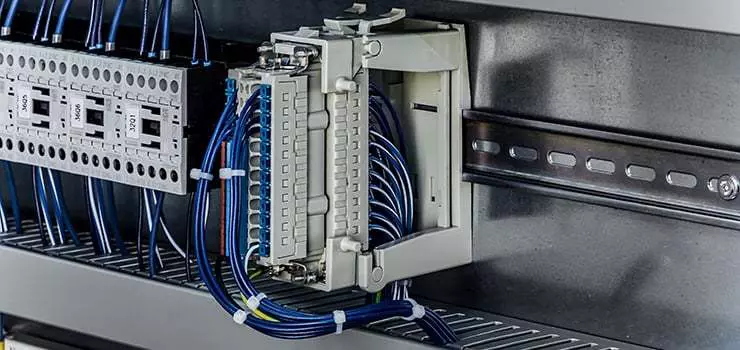

One of the core requirements of flexible production is the ability to quickly install machines and modules, reconfigure them at will and operate them without disruption. The tool-less rapid termination technology Han® ES Press is based on the proven cage clamp, and is consequently reliable and vibration-proof.

Easily bridging contacts in inserts of industrial connectors

In the past, additional components or complex cable assemblies were needed to bridge contacts, but now, for the first time, the jumpers can be used directly on the insulation body.

Various longitudinal and transverse bridges ensure reductions in space and time and also allow star and delta circuits in addition to potential multiplication, e.g., to connect sensors.

Optimised for fast assembly in the field as well as easily bridging contacts – the Han® ES Press connector

Cutting installation time by up to 50%

Customers can profit from faster termination times during series production wiring while still retaining the full functionality in field installation.

No matter whether you use stranded wires with or without ferrules - you will reduce the installation time by up to 50% compared to other termination technologies.

With its Han® ES Press HMC series, HARTING has developed suitable interfaces that can be installed quickly without tools and are extremely robust – meaning they can handle at least ten thousand mating cycles.

Additional time savings for the assembly of cabinets

The new connectors of the Han-Eco® B series provide valuable time advantages for equipment using the Han® B industry standard. For installation, both ends of the cable harnesses can be rear-mounted from the inside of the switch cabinet into the bulkhead-mounted housing. The rear mounting option considerably simplifies the assembly of cabinets and therefore saves time and money.

Your benefits at a glance:

Easily bridging contacts in inserts of industrial connectors

Reducing costs by using plug-in jumpers

Cutting installation time by up to 50%

Simplified troubleshooting in mounted state

Mating compatible with existing series