Single Pair Ethernet

From sensor to cloud without barriers: SPE is the enabler for the IIoT. With just one pair of wires, SPE makes the field level smart - saving space and costs.

Single Pair Ethernet (SPE) transmits data via Ethernet at speeds of up to 1 Gbit/s with just one wire pair, making it the perfect solution for IIoT and barrier free communication between sensor and cloud. Discover HARTING solutions for Single Pair Ethernet connectivity and cabling and learn about SPE use cases, standards, the ecosystem and why Single Pair Ethernet is the ideal enabler for the IIoT.

Jump to

Single Pair Ethernet explained easily

Your quick start guide: Get to know Single Pair Ethernet in our free eBook and short videos.

What is Single Pair Ethernet?

Single Pair Ethernet (SPE) is a new technology standard that transmits data via ethernet at speeds of 10Mbit/s to 1GBit/s with just one pair of wires, making it the perfect infrastructure solution for IIoT and smart factories. At the same time, Single Pair Ethernet enables the power supply of terminal devices via Power over Data Line (PoDL). Transmission distances of up to 1000 meters make Single Pair Ethernet particularly interesting for use in process automation.

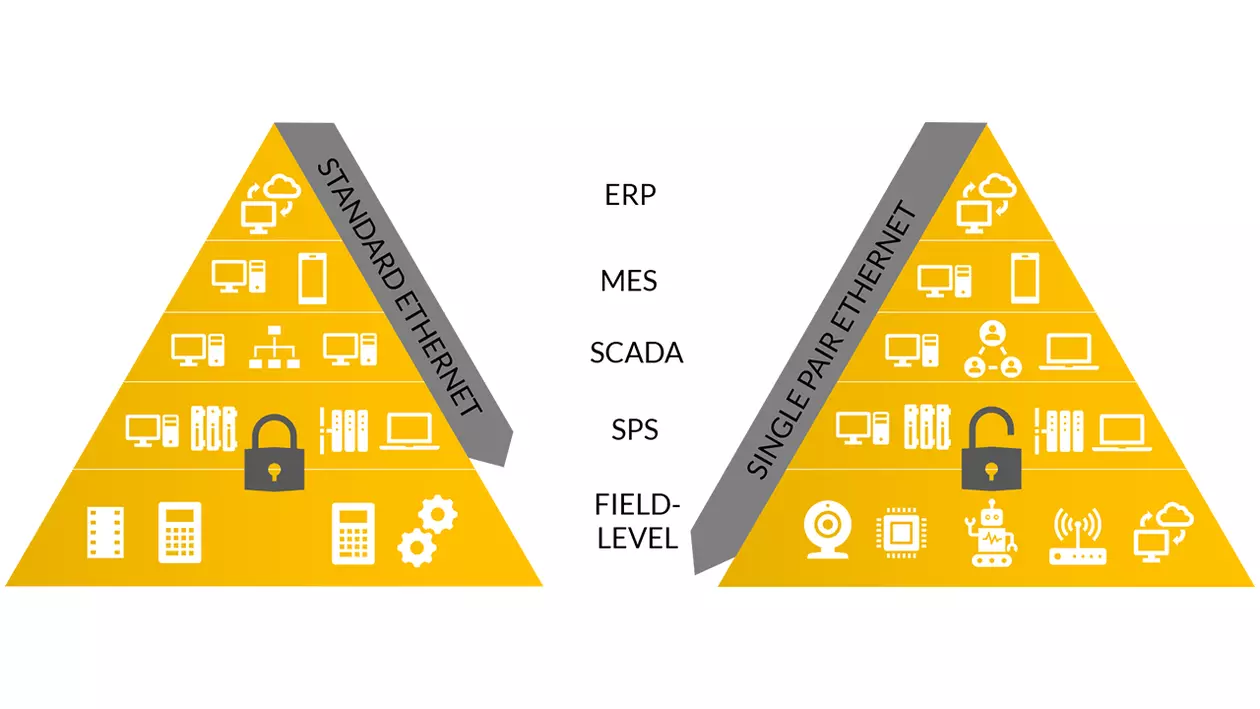

The field level gets smart

Single Pair Ethernet makes the field level smart. It permits the barrier-free connection of equipment, sensors/actuator technology and much more via end-to-end IP-based communications up into the field level. By being able to integrate Ethernet interfaces onto simple sensors, cameras, reading/ID devices or similar equipment, it becomes possible to implement Integrated Industry and IIoT.

SPE delivers a decisive advantage compared with bus systems or analogue current/voltage interfaces, as can still be found in the field level today. Using SPE simplifies the parameter setting, initialisation and programming. The set-up, operation and maintenance of equipment becomes more efficient and more cost-effective. SPE in machines, robots and in rail technology also help to save weight and space. The complete wiring is simpler and also considerably faster to install.

The advantages of Single Pair Ethernet

Transferring data at Gigabit speed via Ethernet with just one pair of wires and simultaneously supplying the devices with power has great potential and offers many advantages.

The demand for Single Pair Ethernet

The trend of digitalization is raising new expectations for communication and cabling technology such as high availability, short access times, fast data transport and the secure transmission of large amounts of data in a wide variety of application environments. At the same time, devices, cables and connection technology should become more powerful, smaller and more robust, as well as offering a high degree of modularity and compatibility. With Single Pair Ethernet (SPE), a new technology is entering the market that meets the new requirements.

Automotive as a pioneer

Single Pair Ethernet is already being implemented in new generations of automobiles, replacing CAN and other bus systems. Controls, communication and safety functions will in future run uniformly via Ethernet. This is a fundamental prerequisite for networked or later autonomous driving.

SPE in industrial automation

The use of Single Pair Ethernet is also worthwhile in industrial automation. Single-pair cabling is fast, space-saving, cost-effective and easy to implement. Equipping simple sensors, cameras and the like with Ethernet interfaces makes SPE a driver of topics such as Integrated Industry and IIoT. This reduces the field level smart and the effort for parameterization, initialization and programming.

How HARTING innovates for SPE

HARTING relies on an alliance of industry, standardisation and research for growing Single Pair Ethernet. As part of this alliance, international standardisation committees have completed a multi-stage selection process in favour of the HARTING Technology Group’s SPE mating face. This also ensures planning security for the designers of new devices or sensor/actuator technology, permitting them to actively commence the implementation of Single Pair Ethernet in the respective device technology.

For HARTING, SPE is a technology topic and the starting point for many new product developments. For the user, however, SPE is not only an opportunity but also a challenge. Is this new technology just as safe as the existing solution? Can SPE also be used in process automation with line lengths of 1000 m? How much power can the end device use? When will SPE connectors and cables be available and will they be adequately standardised? HARTING takes these questions very seriously and has decided to answer them as part of a technology partnership.

The program WIPANO ("Knowledge and Technology Transfer through Patents and Standards") is an initiative of the Federal Ministry of Economic Affairs and Energy which helps to achieve this. HARTING, the University of Reutlingen and LEONI are working together in the NG200 joint project on urgent SPE issues and are simultaneously integrating their results into the international standardisation process. Recently, with the IEC 61076-6, an important step has been made towards specifying weight- and space-saving cabling for an industry-compatible single-pair mating face.

Single Pair Ethernet - FAQ

Single Pair Ethernet (SPE) ensures for the first time the cost-effective use of Ethernet in every aspect of industrial automation. Single pair Ethernet uses one pair of wires to transmit data at speeds up to 1GBit/s. This makes SPE ideal for industrial applications in the age of Industry 4.0 and IIoT. This free eBook entitled Single Pair Ethernet provides detailed information on single pair Ethernet.

Conventional Ethernet requires two or four pairs of wires. In comparison SPE only has one pair. This helps to reduce costs and weight, and thanks to its smaller size, it enables access to new devices and to the resulting industrial field level. SPE therefore forms the basis for IIoT.

Power transmission has also been standardised for the new SPE transmission standards. PoDL Power over Data Line is the term used to describe effective power supply of up to 50W.

The Ethernet technology based on IEEE 802.3bp 1000BASE-T1 is already available today and delivers 1 Gbit/s transmission speed over only one pair of copper wires. IEEE is currently working on a further standard for even higher data rates up to 10 Gbit/s (IEEE 802.3ch), which are required for high-resolution sensors and video transmissions. In addition, a standard for only 10Mbit/s (IEEE 802.3cg) is being developed. This standard enables transmission distances of up to 1,000 metres and can therefore replace almost all fieldbus types.

Development of SPE began with the BroadR-Reach Standard that was developed by the Broadcom Corporation. After the automobile industry, which needed a replacement for the CAN bus, identified this new TCP/IP-based transmission method, the IEEE 802.3 working group released the first SPE standard as standard 100BASE-T1 in IEEE 802.3bw-2015 clause 96. SPE is snow being adapted to the requirements of industry.

With universally standardised SPE infrastructure, for the first time it is feasible to use Ethernet at the field level from the cloud through to the sensor-actuator networks. This prevents disruptions in data processing and creates a unified basis for communication. It has made IIoT possible.

The following standardisation projects for SPE connectors are currently being drawn up:

IEC 63171 – Basic standard with all the necessary specifications and test sequences (CD in preparation)

IEC 63171-1 – SPE connectors by CommScope based on the LC interlocking for M1I1C1E1 applications (CDV available)

IEC 63171-2 – SPE connectors by Reichle & De-Massari for M1I1C1E1 applications (CD available)

IEC 63171-3 – SPE connectors from the company Siemon based on one pair of well-known Tera connectors for M1I1C1E1 applications (NP available)

IEC 63171-4 – SPE connectors by BKS for M1I1C1E1 applications (NP available)

IEC 63171-5 – SPE connectors from the company Phoenix Contact based on the IEC 63171-2 connector face for M2I2C2E2 and M3I3C3E3 applications (CD available)

IEC 63171-6 (formerly IEC 61076-3-125) – SPE connectors from the companies HARTING and TE Connectivity for M2I2C2E2 and M3I3C3E3 applications (CDV available, FDIS in preparation and final publication 2019)

In automation, SPE enables field levels to be connected using Gbit/s Ethernet. This makes disruptions in data processing a thing of the past and with TSN every sensor has real-time capability.

Every 100 meters of SPE cable weighs about 1.6 kg less than standard Ethernet cable. With this weight reduction, a train operator can save about 14,000 Euro in operating costs.

With only one pair of wires, SPE cables are much thinner making them more flexible than standard Ethernet cable. The thinner the cable, the more it is able to withstand bending and torsion cycles. The result is a longer service life and cost savings. SPE is therefore the ideal cabling for future robotic applications.

This is known as cable sharing and involves the transmission of SPE over four-pair Ethernet cable. While it is theoretically possible but not practical. The transmission lengths for 1GBit SPE is currently limited to 40 meters. To ensure safe transmission, the cable would have to meet Cat. 7 standard. This is rarely the case. SPE should be seen as a practical addition to the Ethernet standard and as a replacement of fieldbusses.

Thanks to very small device sockets, SPE is the ideal technology for modern camera sensors in industrial applications. They need high data rates via a small and compact interface. Our HARTING T1 Industrial meets these requirements in accordance with IEC 63171-6.

The SPE Industrial Partner Network is the first point of contact for users who want to set up SPE networks or devices. All member companies see Single Pair Ethernet as the basis for fast and sustainable growth of the Industrial Internet of Things (IIoT). The partner network operates its own website around.

T1 Industrial - Single Pair Ethernet

Transmission of Ethernet via just one single pair of copper wires. SPE is the perfect technology to connect field devices to the Ethernet network. Single Pair Ethernet technology is fast, space-saving, cost-efficient and ready to implement. The equipping of simple sensors, cameras and more with Ethernet interfaces positions SPE as the driver of topics like Integrated Industry and IIoT.

Available as: CABLE CONNECTOR | CABLE ASSEMBLY | DEVICE SIDE

Single Pair Ethernet standards

Barrier-free data transfer between Cloud and field level - Single Pair Ethernet is changing industrial communication. To make SPE technology widely available, the compatibility of devices, cables and connectors is a top priority. This is ensured by international standardization.

IEC 63171-6

With the publication of IEC 63171-6 in January 2020 by the IEC standards committee SC 48B for connection technology, the Single Pair Ethernet standard has been set. The mating face standard IEC 63171-6 T1 Industrial Style was the first standard submitted by HARTING to SC 48B for a Single Pair Ethernet mating face as early as 2016. The publication of this standard gives users a reliable investment basis for future-proof IIoT networks based on Single Pair Ethernet.IEC 63171-6 (Industrial Style) is a complete standard document with all necessary specifications and test sequences, which is incorporated into current SPE cabling standards of the ISO/IEC 11801-x series of standards for structured cabling.

The implementation of SPE in the ISO/IEC 11801 documents is very important because only in this standard, the cabling channels are described with all necessary parameters (length, number of connections, bandwidth and the complete set of transmission parameters including NEXT, FEXT, shielding properties etc.) with relation to the environment - MICE and can therefore be metrologically verified after installation.

This connection of component standards to connectors and cables provides all users of SPE with clear guidelines for the construction and testing of appropriate transmission links.

The use of cabling components other than those described in ISO/IEC 11801-3 Amd.1, for example, is possible in principle, but then they no longer conform to the standard and carry the risk of incompatibility and loss of function. For this reason, ISO/IEC JTC 1/SC 25/WG 3 and TIA TR-42 launched international selection processes at the beginning of 2018 to define uniform interfaces. These two selection processes were co-initiated by IEEE 802.3, which requested a recommendation for a SPE Media Depended Interface (MDI) from ISO/IEC and TIA.

More than 20 national expert committees participated in this selection process. As a result of this selection process, the mating face according to IEC 63171-6 based on the proposal from HARTING T1 Industrial has become generally accepted for industrial and industry-related applications (M2I2C2E2 and M3I3C3E3).

Single Pair Ethernet ecosystem

Global technology leaders stand behind IEC 63171-6 and IEC 63171-7

Standardised and uniform interfaces are the key to enabling manufacturers to jointly develop the SPE-EcoSystem from sensors, actuators, control units and connection technology and users to create suitable automation solutions from these components.

Founded in 2019, the SPE Industrial Partner Network, a global association of renowned technology leaders, has set itself the task of advancing SPE as a technology for the rapidly growing IIoT market. It offers the emerging

The Partner Network provides clear recommendations for the development of future IIoT applications, is the central information platform and offers security to users that the technology is to be relied upon.