Termination technology

The most common termination techniques can be assembled into Han® connectors. Special inserts and contacts are available to match the particular techniques of wire termination. The choice of the right termination technique depends mainly on the type of cable, the cable cross-section, as well as the number and type of contacts. In addition, all termination types offer different advantages for different production conditions.

Experience all termination technologies during our Web-Seminar "Termination Technologies and Tools"

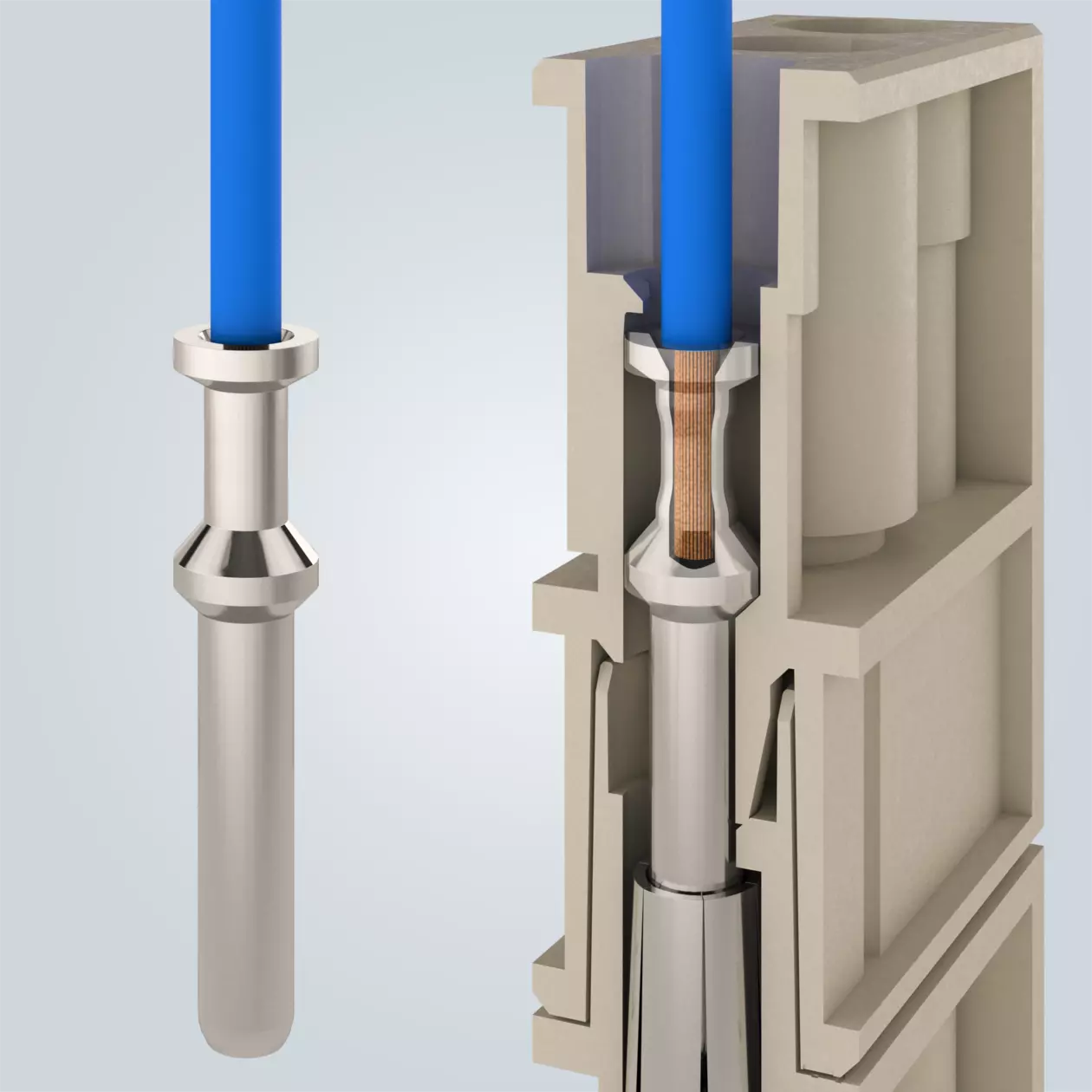

Crimp termination

Crimp termination

Ideal for the pre-assembly of connectors in large quantities due to its suitability for quick wiring

Using the appropriate crimp tools, a consistent crimp quality with excellent corrosion resistance properties can be achieved, almost comparable to cold welding

Due to the high contact density, only very little space is required

How-to-Video

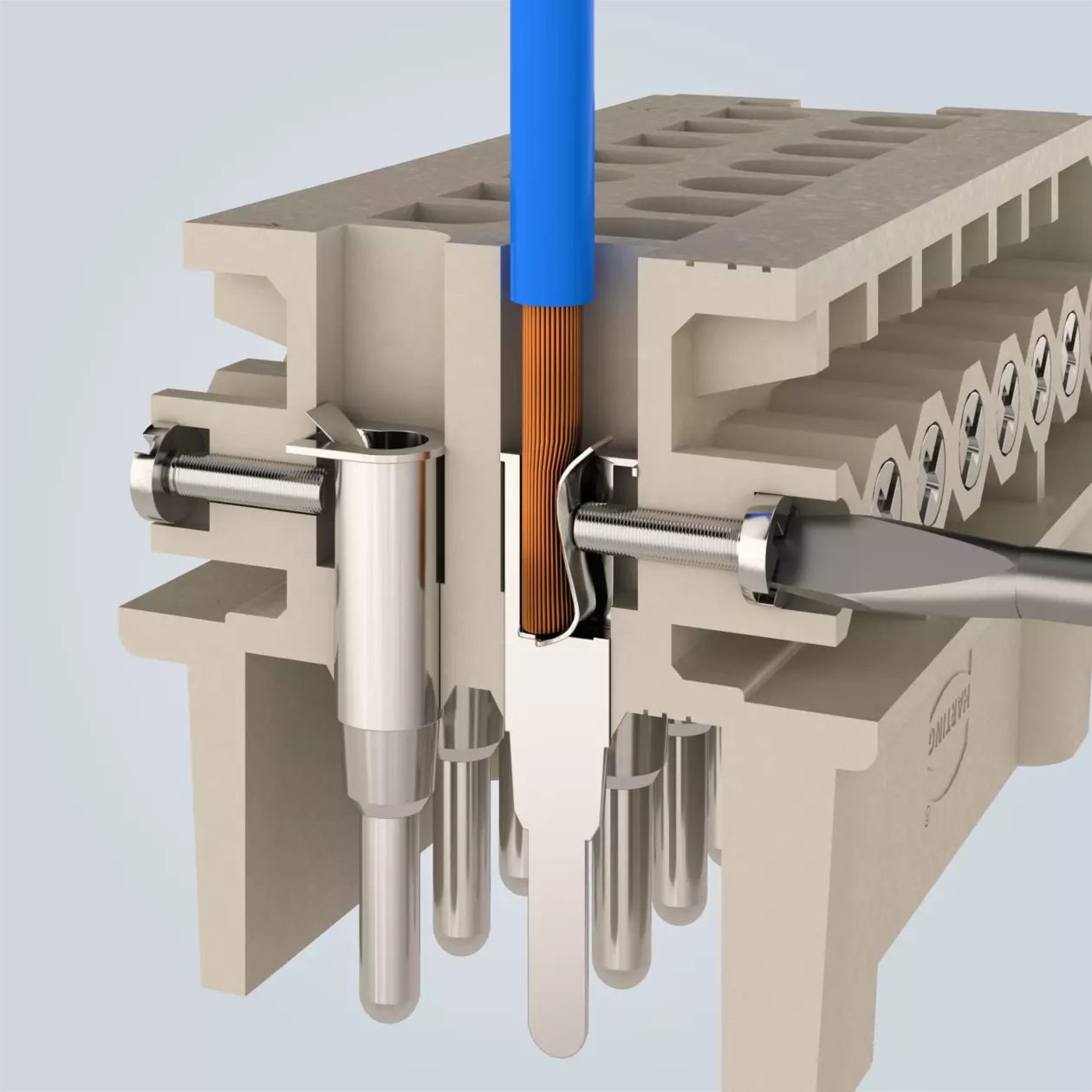

Screw termination

Screw termination

Simple and intuitive to operate

Can be installed on-site without any special tools

Screw termination with wire protection, also to be used for stranded wires

How-to-Video

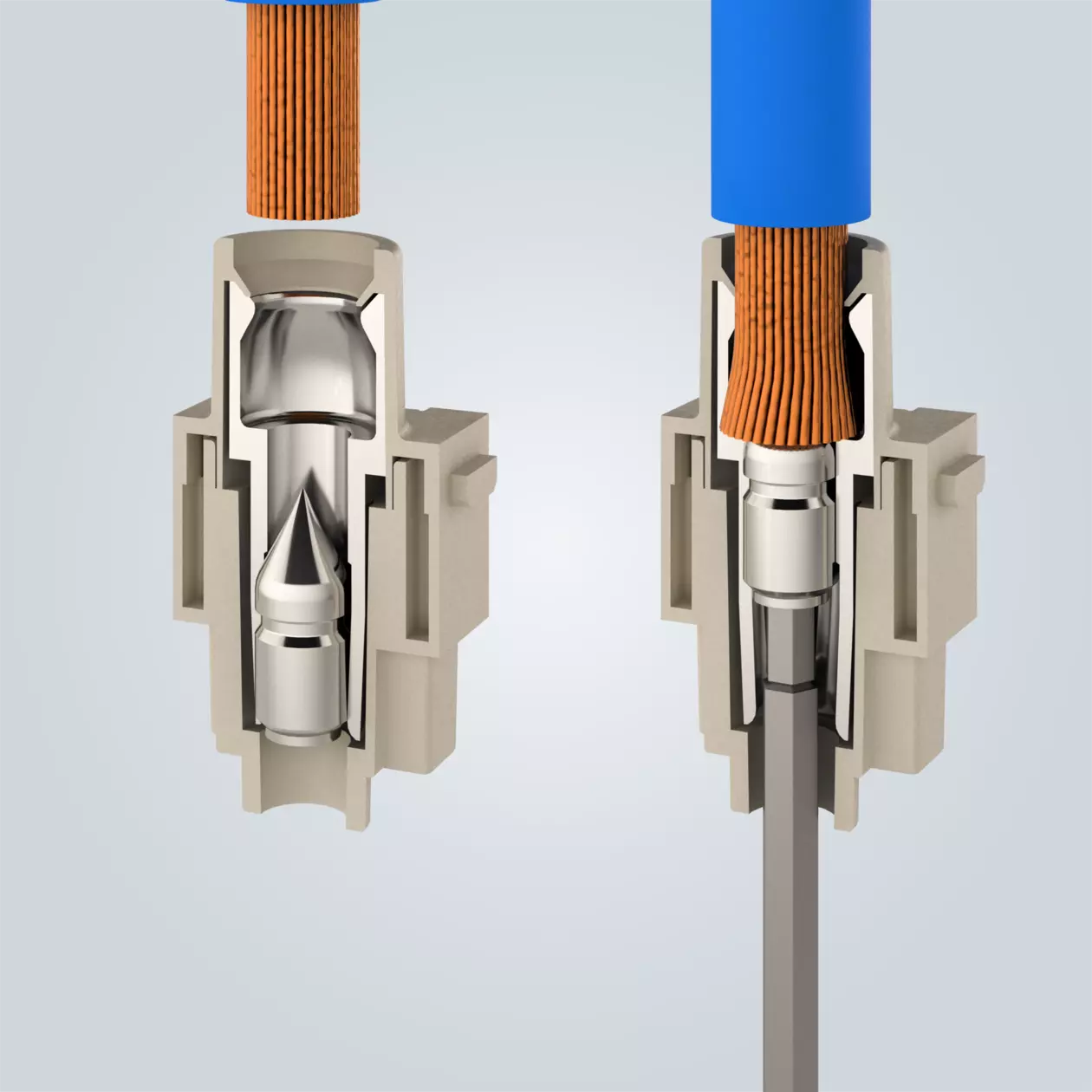

Han-Quick Lock®

Han-Quick Lock® termination

Combines the reliability and easy handling of the spring termination technique with the minimal space requirements of crimp contacts

Can be installed on-site without any special tools

Stranded wires can be quickly terminated

How-to-Video

Axial screw termination

Axial screw termination

Combines the simple handling of the screw termination technique with the minimal space requirements of crimp contacts

Can be installed on-site without any special tools

Suitable for finely stranded wires with large cross-sections

How-to-Video

Cage clamp termination

Cage clamp termination

Simple and convenient handling without any special tools

For solid and stranded wires from 0.14 to 2.5 mm²; higher clamping forces with increasing conductor cross-sections

Excellent functional safety: wire connection is resistant to vibration/shock and has a consistently low voltage drop

How-to-Video

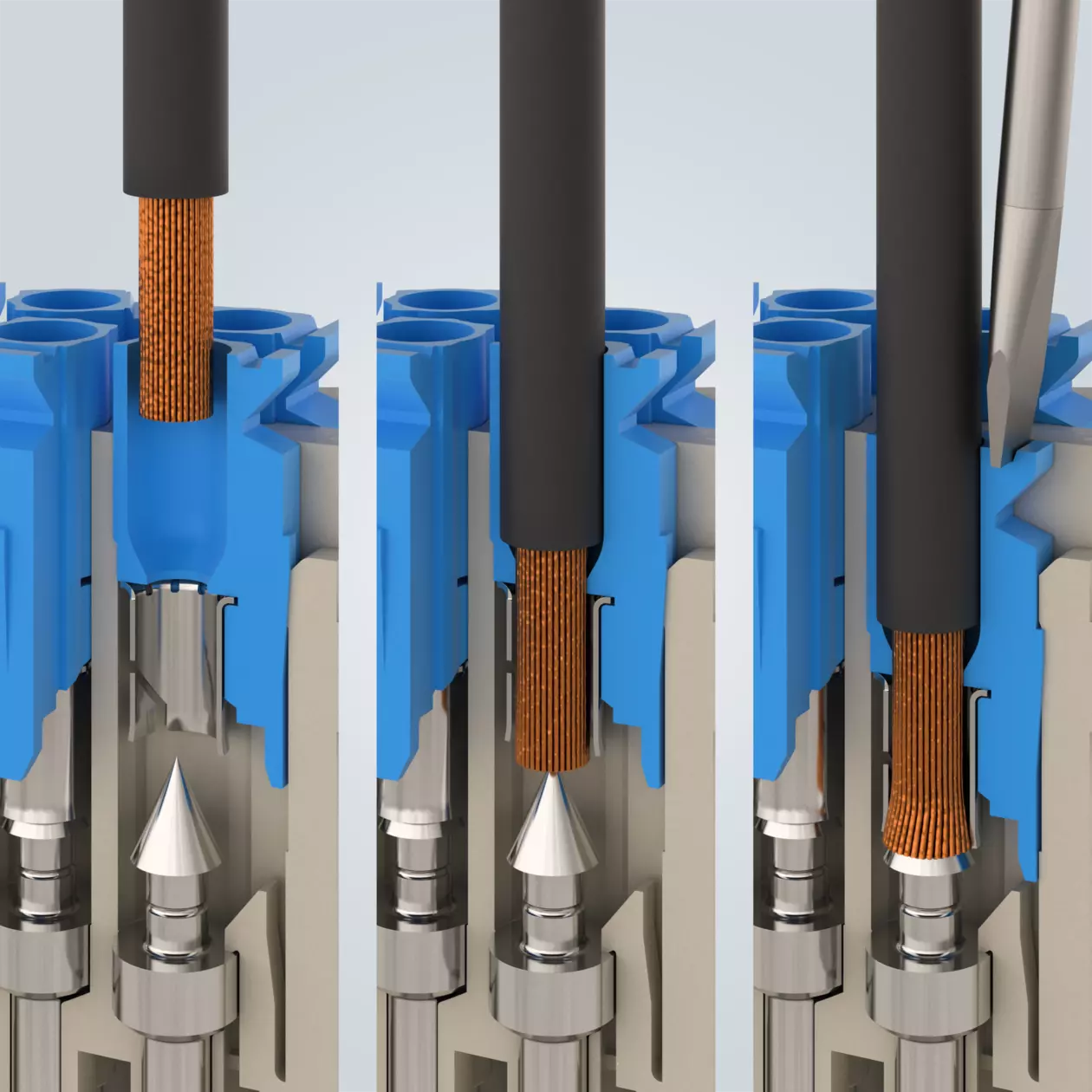

Han® ES Press

Han® ES Press rapid termination technology

Tool-less rapid termination technology

Integrated plug-in jumpers

Cutting installation time by up to 50%

How-to-Video

IDC termination technique

IDC termination

Quick and easy to connect, without soldering, screwing or stripping (LSA technology)

Suitable for solid wires, especially those with small cross-sections