More efficient energy consumption and reduced complexity are major trends in the railway industry. Manufacturers of railway vehicles are always looking for ways to reduce the weight of their vehicles. What’s more, installation processes need to be clear and understandable to save time for the assembly teams. With the new Han® HPR TrainPowerLine (TPL) HARTING have developed a new interface to meet all these requirements.

Alternative for UIC 552 interface

The Han® HPR TrainPowerLine replaces existing solutions such as UIC, power or Y-distributors for train busbars. The complexity of the application was reduced considerably at the customer's request: a uniform solution now replaces the many variants that were previously required for busbar construction.

The number of parts used has been reduced. At the same time, safety is a top priority: male and female contacts are designed to be touch-proof, and there are ground potentials on the top and bottom of the housing.

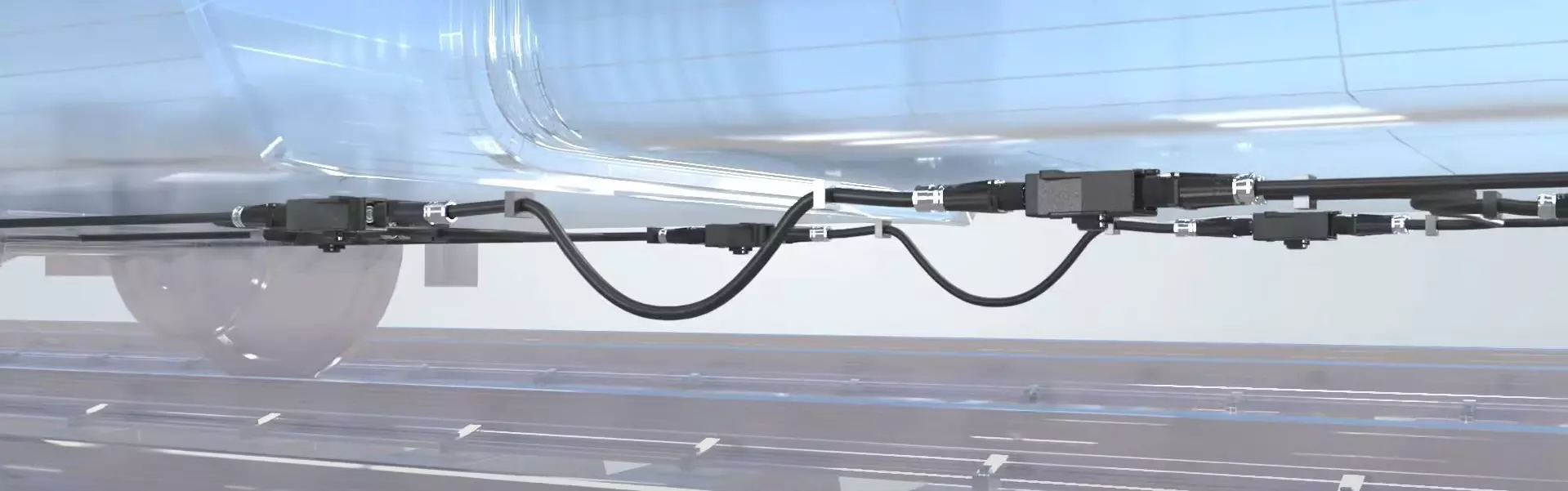

Previously interfaces for the underfloor were often hard-wired. The TPL is designed so that all connection points are now pluggable. The housings are equipped with Han® HC Modular high-current contacts that transmit power up to 800 A / 5100 V DC / 3000 V AC.

Typical environment for the Han® HPR TrainPowerLine are underfloor applications as an alternative to the UIC 552

HARTING Han® HPR TrainPowerLine - Efficient power distribution for railway vehicles

Weight savings up to 10 KG per wagon

The result of developing the Han® HPR TrainPowerLine is a uniform connector design for the entire underbody distribution of a train. The advantages are obvious and range from shortened installation times to more economical use of materials, weight reduction and standardised processes in assembly.

It is tailored to modern trains running in a network and offers weight advantages of up to 10 kilograms per wagon compared to previous standards in the market. Very little space is required to reliably supply all the electrical equipment and systems of the train.

Complete Han® HPR TrainPowerLine interface with three single poles

Designed for a longer lifetime

The housing is based on the Han® HPR design and is made of corrosion-resistant aluminium die castings. The TPL is therefore ideally suited for use in the harsh environmental conditions of outdoor applications. The contours of the main body remove dirt and ice to the sides effectively.

Typical applications are not just underfloor as an alternative to the UIC 552 interface. Vehicle roof applications are also possible with the new highly flexible system from HARTING.

Main body of the Han® HPR TrainPowerLine with closed cover

Your benefits at a glance:

Weight savings of up to 10 KG per wagon compared to the well-known UIC 552 interface

Time savings due to reduced complexity and a clear structured system, based on fewer components

Failure reduction during installation due to a pre-assembled main body

High flexibility due to one system, compared to existing solutions in the market