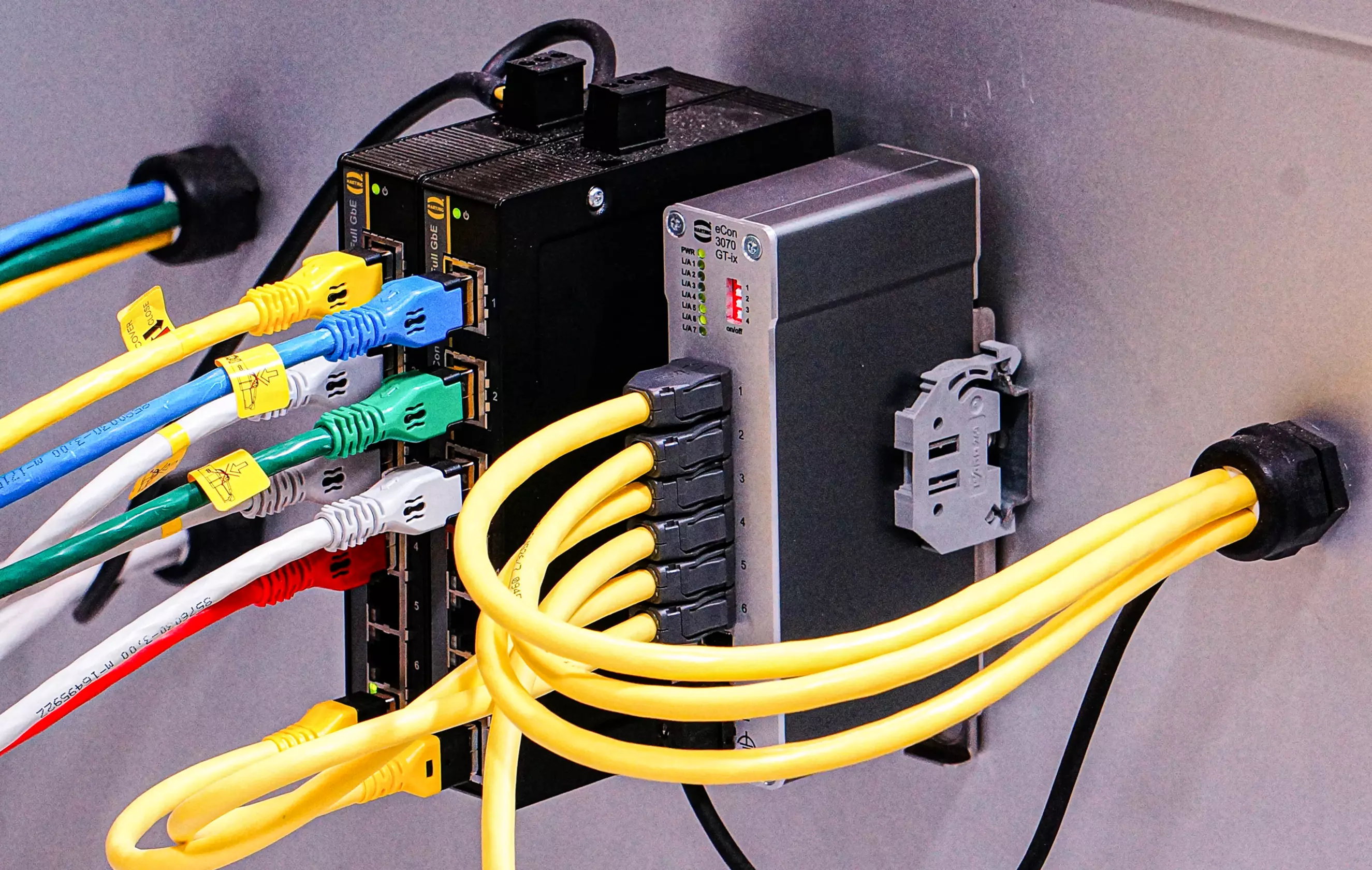

Device connectivity

Smaller, faster and robust at the same time: our modular device connectivity technology can meet the toughest demands and is absolutely reliable.

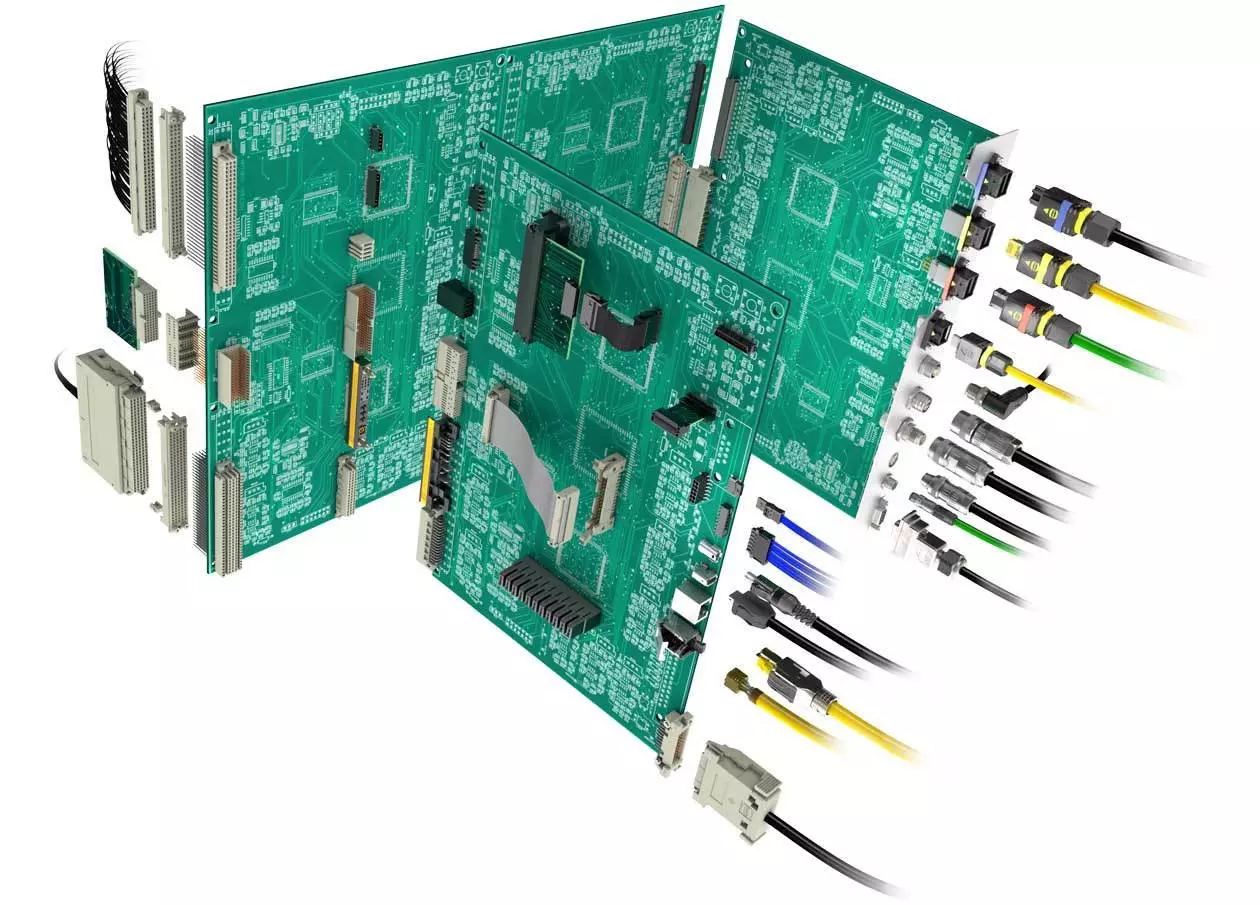

With HARTING you will always find the right solution for all necessary plug connections. Whether for the transmission of data, signals or power into or out of a device or for the connection of printed circuit boards within devices and taking into account the planned operating environment and its conditions: our portfolio offers a wide range of connectors and solutions in the best available quality.

Learn from our experts

Get updated and learn: watch all recordings of our annual digital conference HARTING Industrial Ethernet Week from February 2024.

Resources

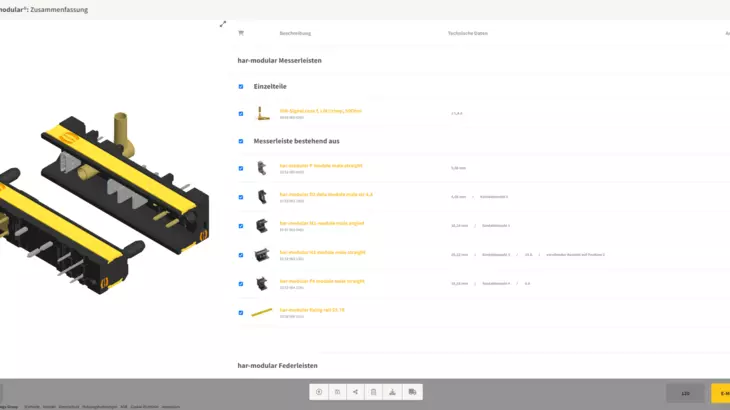

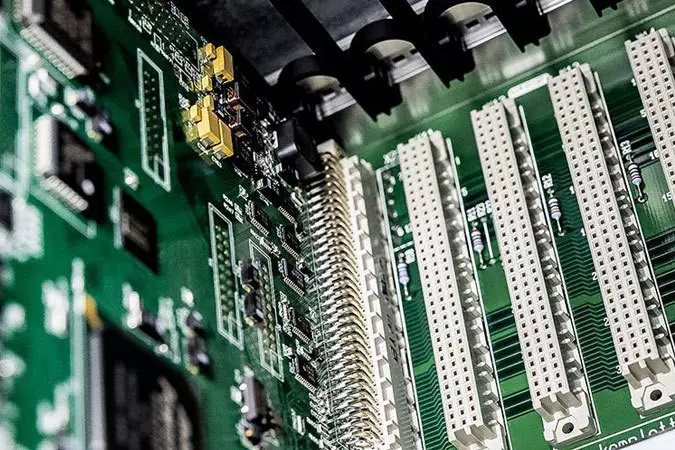

PCB Connectors

PCB connectors are divided into two applications. The first is the connection of printed circuit boards to each other inside the device. The second case is the connection from the PCB to the outside of the device. Each device relies on inputs and outputs. Here, the connector leads directly from the PCB through the housing wall and provides the IP20-IP67 protected connection to the device connection. In addition to classic PCB connectors, HARTING also offers a versatile range of PCB sockets for every application. All HARTING connectors for PCBs can be assembled with common connection technologies.

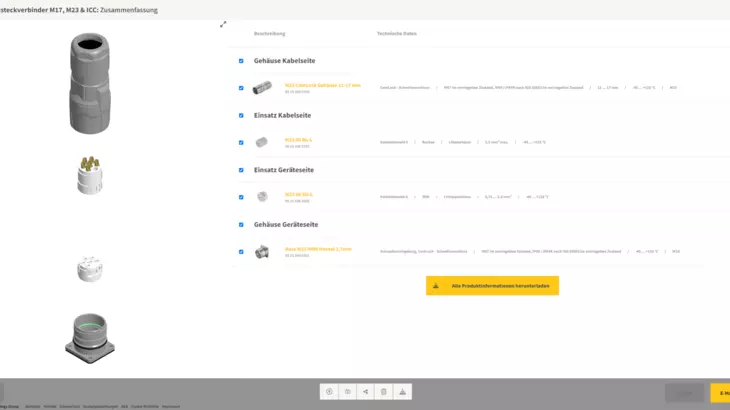

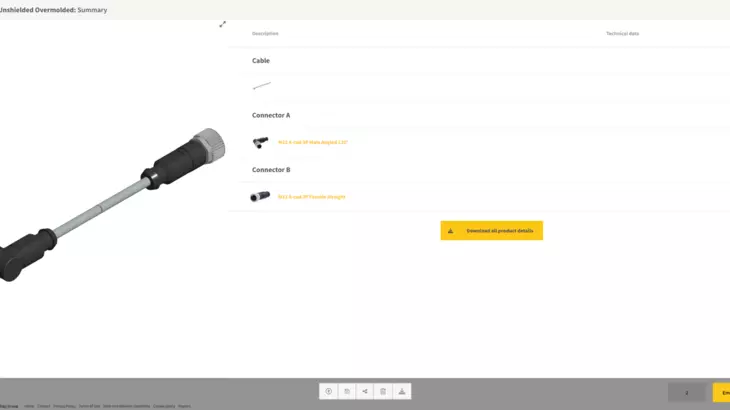

Cable Connectors & Cable Assemblies

Cable connectors are used to transmit the industrial lifelines of data, signals and power. They provide the detachable connection between devices and thus ensure a contemporary and flexible structure of networks and industrial productions. Special attention is paid to the selection of the right connection, suitable for the application. Depending on the application, connectors and their matching counterpart, the socket in the device, must meet special requirements. They must be robust, shielded against electromagnetic influences, sealed against water and dust, and should be as easy and safe to connect and operate as possible. Depending on the requirements, cable connectors and raw cables must be assembled on site. If the connection lengths are clear, ready-to-use cable assemblies make sense.

Panel Feed-throughs (PFT)

A Panel Feed-through (PFT) is an interface from inside to outside through a housing wall. To the outside, a standardized connection point is usually provided, often in protection class IP65/67 or even just IP20. On the inside, either the same interface is designed as IP20 or open cable ends are available. On the inside, in comparison to the PCB bay, direct mounting on a PCB is not possible. The WDF is ready for operation when it is screwed into the corresponding wall cutout.

Configurators

Engineering Data & Services

CAD data, product data manager, distributors availability, free samples & more.

Discover the HARTING Engineering Data & Services to support your project as best as possible. For each product in our digital catalogue you will find further engineering data and services:

CAD data, data sheets and type sheets

Product selectors with multiple attributes

Individually data packages

Configuration and customization

Individual notes and deratings

Free sample service