Cable termination technology

HARTING connectors can be connected using conventional termination techniques. The proper termination technology is selected based on criteria such as cable type, cable cross-section, contact type and number of contacts. Discover our wide range of termination options.

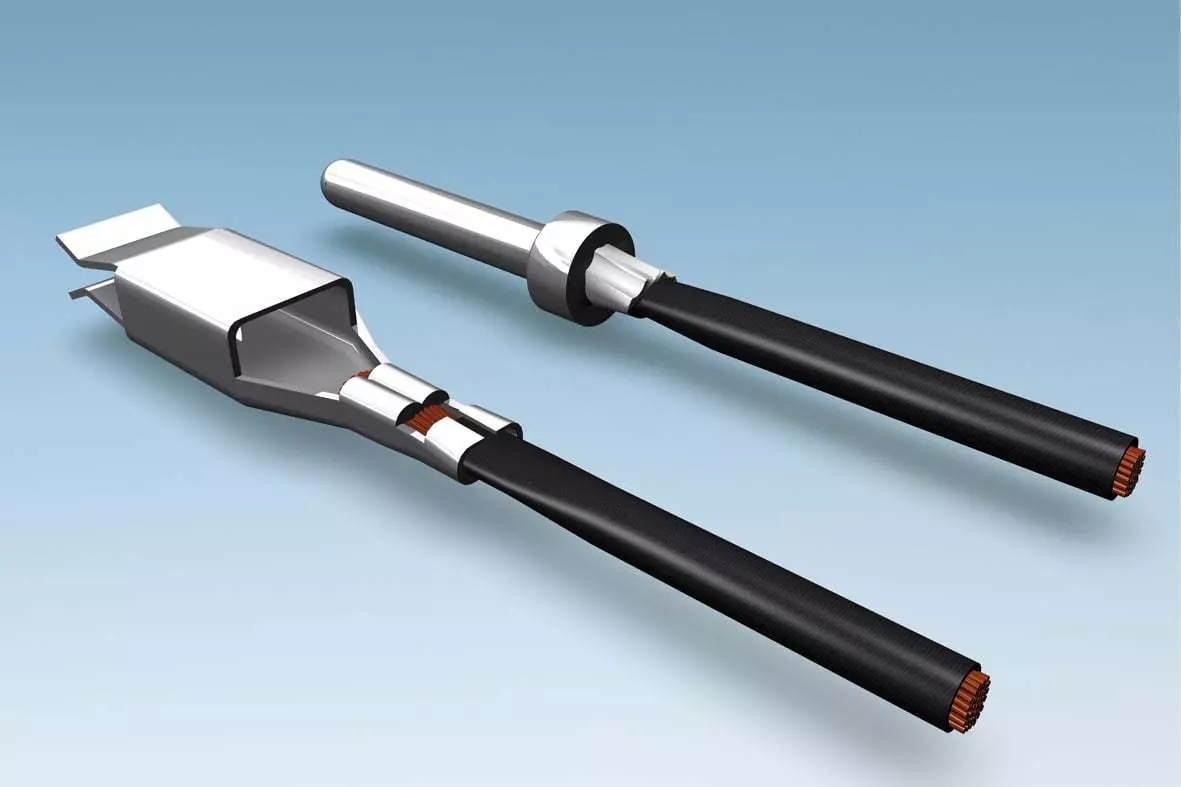

Crimp termination

Gas-tight and miniaturised contacts are synonymous with crimp technology. In crimp terminations, a flexible conductor is enclosed in a gas-tight manner within the crimp contact by controlled deformation. This technique virtually produces a cold weld, thus ensuring the optimum resistance to ageing and mechanical stress from shock and vibration. Automatic crimping machines enable an efficient production of pre-assembled system cables – but crimping technology can also be implemented on-site when using the appropriate tools. The technical requirements for crimping technology have been standardised in IEC 60352-2.

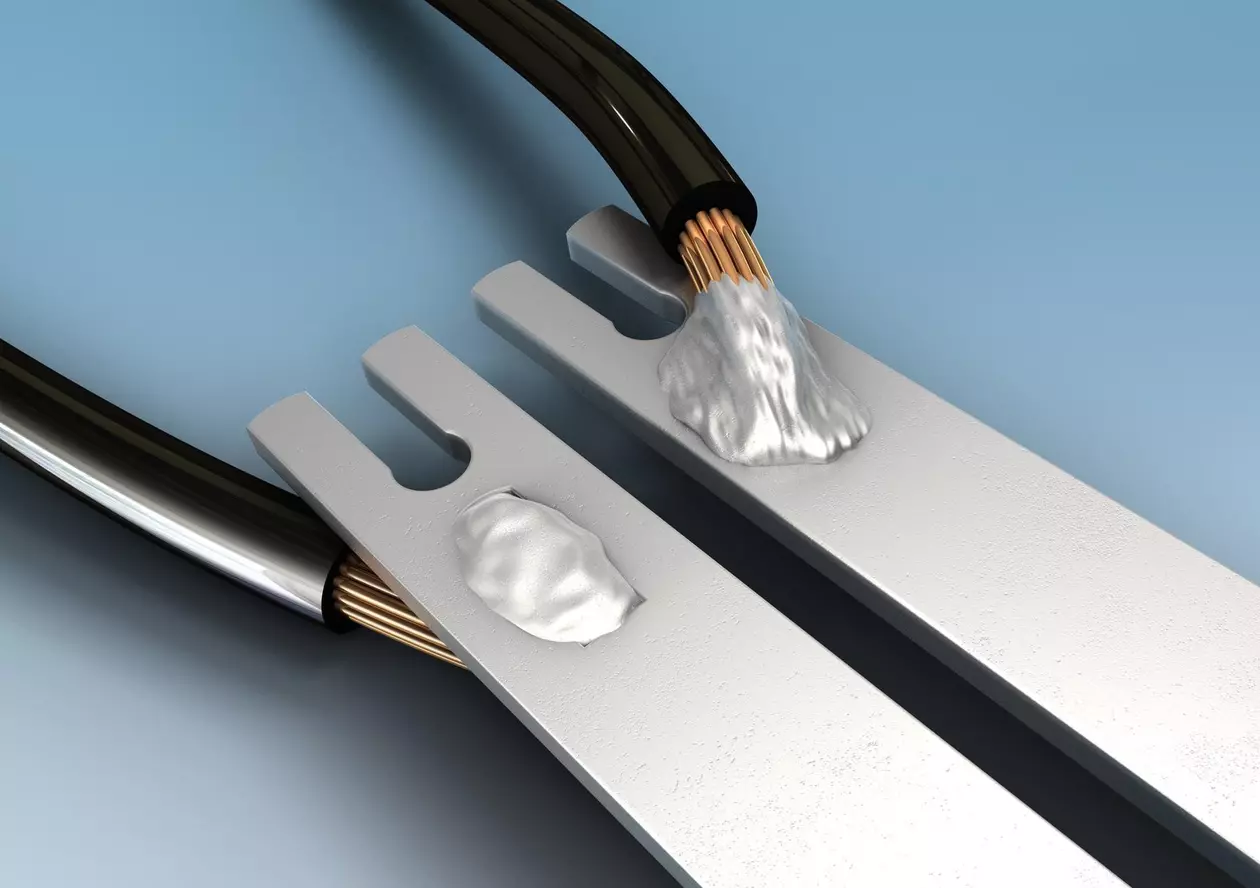

IDC insulation displacement connection

IDC (insulation displacement connections) can be used to provide easy and safe contacting for solid and stranded wires. In a single step, the IDC cutting terminal penetrates into the wire insulation and resiliently contacts the wires. This gas-tight connection ensures outstanding safety for even the smallest currents and voltages. The technical requirements for IDC technology have been standardised in IEC 60352-3.

Solder lug termination

The solder lug termination is the optimal solution for small batch sizes and prototype production runs. Even without using any special tools, a wide variety of cables can be connected to their corresponding cable connectors. The stripped and tinned wire is soldered individually by hand to the solder lug. However, this terminating connection should only be made by trained specialists.

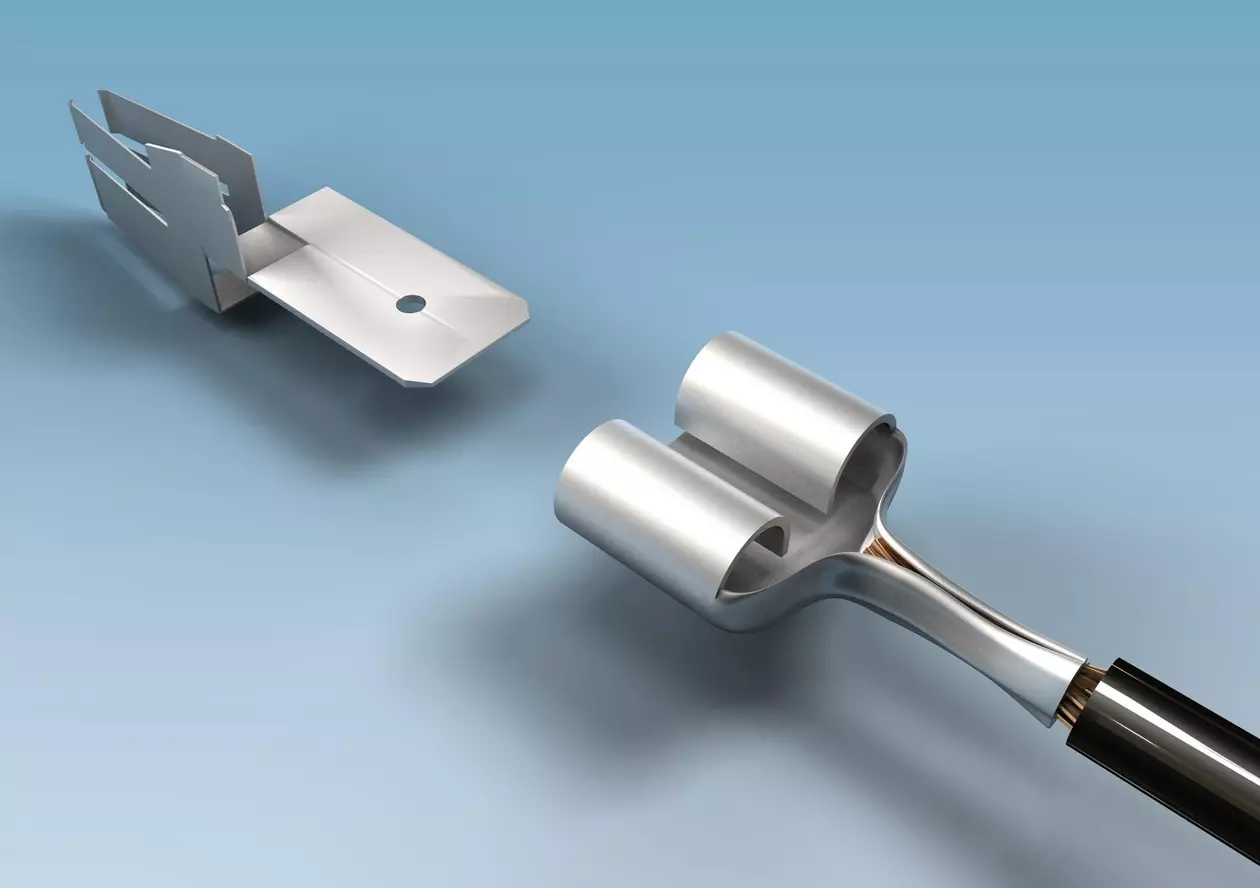

Faston termination

The Faston termination can be used for freely wired connections. It offers the advantages that it can carry high currents (up to 15 A) and is easy to change.

Cage clamp termination

The cage clamp termination technique use a spring to establish contact with flexible and solid conductors. After the spring has been opened by an actuating element, the stripped conductor can simply be inserted into the open contact chamber. This connection technology requires little operating and tooling efforts. It also features excellent functional reliability. Multiple connections can be made because of the spring-loaded connection. This connection is extremely resistant to vibration and shock.

HARAX® termination

HARAX® is a toolless rapid termination technique from HARTING. The contact is established via insulation displacement contacts. M8 / M12 circular connectors with HARAX® connection can be easily assembled by hand on-site.

preLink® insulation displacement termination

preLink® is based on insulation displacement technique and is used for data connectors up to 10 Gigabit/s. The wires are fed into a cube-shaped termination block and crimped/contacted and shortened in one operation using assembly pliers. This termination block can be clipped into M12 circular connectors as well as matching RJ45 connectors, cable couplings or PCB sockets. The mating face can be changed in seconds at any time.