Retrofit Solutions for Rail Vehicles

For economic reasons, rail vehicles are designed for a long-term service life. In order to keep these vehicles functional over decades, HARTING offers tailor-made retrofit solutions as well as long-term suitable replacement components and cable assemblies for all application areas in a rail vehicle. Relying on our development expertise, we work out retrofit solutions that guarantee a sustainable, economical product strategy for the next few decades.

Standardised technology level throughout the entire train

Modernisation is not just the renewal of a single rail vehicle. On the contrary, the entire train must reach a technology level that meets the same standards throughout. This can be achieved with suitably designed inter-car connection solutions, e.g. so-called jumper cables, which ensure the smooth transmission of power, data and signals throughout the entire train. In addition to the individual design and manufacture of these jumper cables, HARTING is also positioned to provide other suitable solutions that will save time and money during the retrofit.

HARTING also offers retrofit solutions for other modules within a rail vehicle, such as bogies, drive and brake units, heating and air-conditioning systems and much more.

Optimal solutions for inter-car connection systems save time and money during the retrofit.

Suitably designed jumper cable with a dummy module intended as a retrofit solution.

Pre-assembly reduces installation time

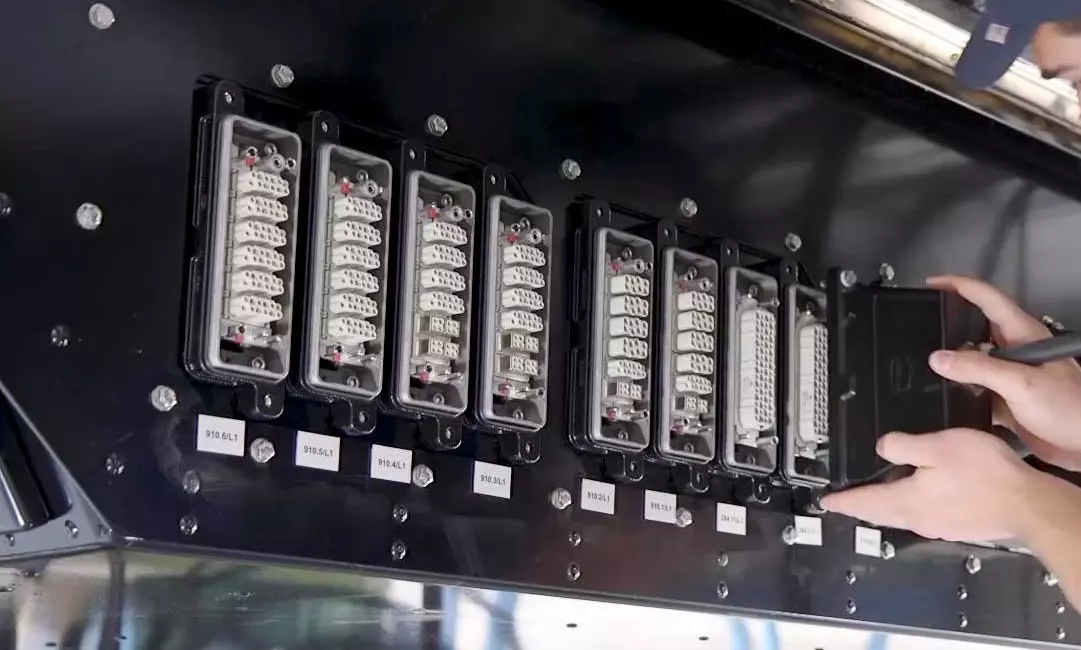

Thanks to pre-assembled connection plates, which allow a high density of connectors in a very compact space, space-saving expansions are possible in a short time span. This reduces the mechanical effort as much as possible, since it is not required to cut a separate opening through the rail vehicle wall or floor plate for each individual connection. In view of the pre-assembly factor, the installation time on the rail vehicle itself is further reduced, while the input required for wiring and testing on the vehicle is also trimmed down. The interface can remain individual and highly flexible, as HARTING connectors - especially from the Han-Modular® portfolio - offer countless combination options.

The use of pre-assembled connection plates significantly reduces installation time on the vehicle.

Thanks to pre-assembled connection plates, space-saving expansions are possible in a short time span.

Retrofit or upgrade of existing systems

The interior of a train also requires modernisation. This means that passenger info and entertainment systems (PIES) must be retrofitted, or at least brought up to the latest technical standard. This also includes information monitors in the rail vehicles but also individual displays at each seat. In the meantime, passengers already expect charging facilities for laptops and smartphones, and a wireless network (W-LAN). Camera systems in the individual train carriages increase the feeling of safety. In order to enable the supply, networking and safe functioning of all systems, HARTING is providing a broad portfolio of both connectors and ready-made cabling solutions. To ensure that these can then also be used individually in "plug & play" mode, HARTING product experts can take on the layout and design enabling the development of suitable retrofit solutions.

In the same way, passengers now expect charging facilities for laptops as well as access to a wireless network (W-LAN).

When it comes to "getting fit" for the future, retrofitting the passenger info and entertainment systems (PIES) is a necessity.

"Getting fit" for the future

In addition to "PIES" components, safety-related systems, however, may also be required for "getting fit" for the future. The European Train Control System (ETCS) forms the foundation for a future uniform train control system in Europe and – over the long term - is intended to replace the numerous different train control systems. Modernisation or retrofitting, for example of Ethernet cabling, will also be necessary for this.

Andre Kelle

Position: Product and Application Manager, Germany

- Company: HARTING Technology Group