Automation Connectivity Devices

No more compromises. Enable your industrial automation machinery to be smaller and more durable, without sacrificing functionality.

Maximize your automation devices

The goal of automation is to maximize manufacturing efficiency — by transferring tasks from humans to machines. As the push for smarter, faster machinery increases, so does the need for more efficient cables and connectors to equip them.

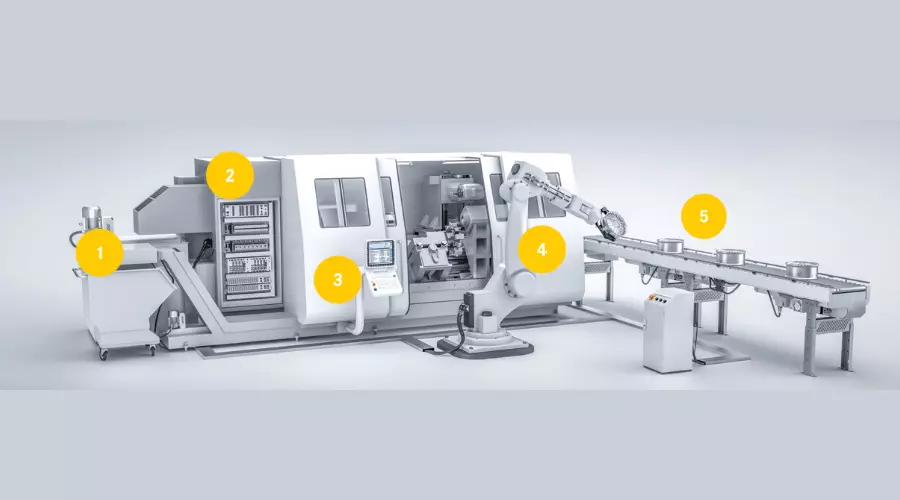

Automation connectivity applications

Connectivity solutions for industrial automation

DATA

Transfer robust amounts of data and increasingly faster speeds, without taking extra space.

Today's automation equipment is being asked to communicate more — machine to human, machine to machine — within less physical area. Unlike legacy connectors, HARTING data transfer connectivity components help make it possible to meet the challenges of today and the requirements of tomorrow.

Next-Gen ix Industrial®:

✓ Built with size in mind

✓ Supports Cat. 6A performance for speeds up to 1/10 Gbit/s

✓ Power over Ethernet (PoE) capabilities for more functionality in less space

✓ 70% smaller and 4x faster than the RJ45 connector

POWER & SIGNAL

Plug-and-go connectors power more productivity, less downtime.

Transfer power and signal within all areas of your machinery with HARTING’s rugged connectivity solutions. Their speed-to-build design and reliability means lower cost of ownership over the long lifespan of the components.

HARTING Hybrid Connectors:

✓ Industrial-strength metal housing stands up to vibration, shock, and constant use

✓ Allows for multiple connection types and sizes within a single connection

✓ Quick-connect design speeds installation and maintenance timelines vs. hardwiring

HARDWIRING VS. CONNECTORS

Connector-based wiring over hardwiring has benefits at every stage of industrial machinery.

Installation Cost & Time

When hardwired control cabinets need to be disassembled, shipped, and reassembled, more costly specialist contractors need to be hired. Lengthy testing to ensure the wiring has been connected correctly takes extra time, as well.

Plug-and-play connectors can be easily linked to each other and machinery, resulting in a simple, flexible, and versatile installation experiences.

Maintenance

Fixing a hardwired machine requires a specialist maintenance engineer or contractor painstakingly troubleshooting to find failure points among thousands of connections. Not to mention the time it takes to remove, replace, or rewire the issue.

Plug-and-play connectors can be disconnected and replaced easily and cost-effectively within seconds.

Flexibility

For decades, hardwiring was an acceptable practice when manufacturing floors did not change their footprint. Build it and forget it? Those days have passed.

Plug-and-play connectors allow production processes to be adapted quickly and simply, and can often be performed by machine operators themselves. With modular connectors, power, control, and data transmission be side-by-side in one connector, saving space and making it easier for specialists to design applications.

Featured automation components

Connect With Our Experts

Our team of Technical Application Consultants is available!

If you’ve got questions about connectorization or our solutions' capabilities, our experts are ready to answer them.

Contact our in-house engineers for technical guidance or design help and let us be the connector specialist extension of your team.

HARTING Product Configurator

Design your next connector, then download documentation in various formats — 3D files for CAD, Bill of Materials (BOM) — for easy collaboration and hassle-free ordering.